Computer Numerical Control (CNC) machining has become one of the most important manufacturing technologies in today’s industrial world. From aerospace parts to medical devices, and from automotive components to consumer electronics, CNC machining plays a central role in producing high-precision, reliable, and scalable parts. Whether you’re new to CNC machining or looking to deepen your understanding, this guide explores what CNC machining is, how it works, and why it continues to be a cornerstone of modern manufacturing.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process in which pre-programmed computer software controls the movement of machinery and tools. Instead of relying on manual machining by an operator, CNC systems automate cutting, shaping, drilling, and finishing operations with exceptional accuracy.

At its core, CNC machining transforms a digital design (CAD file) into a physical part by removing material from metals, plastics, or composites. The entire process is computer-driven, ensuring consistent results even on complex geometries.

How CNC Machining Works

CNC machining follows a step-by-step digital workflow that ensures precision and repeatability:

1. CAD Modeling

Every CNC project begins with a CAD (Computer-Aided Design) model. This 3D digital blueprint defines all specifications of the part, including dimensions, geometry, tolerances, and materials.

2. CAM Programming

The CAD file is imported into CAM (Computer-Aided Manufacturing) software, which converts the design into G-code—the language CNC machines understand. This code directs tool paths, cutting speeds, feed rates, spindle rpm, and movement patterns.

3. Machine Setup

The machinist installs the required tools, secures the workpiece, and aligns everything accurately. Although CNC machining is automated, proper setup ensures quality and safety.

4. Machining Process

The CNC machine executes the programmed instructions. Depending on the project, machining may include:

-

Milling: Rotating tools remove material from the workpiece.

-

Turning: Material rotates while a stationary cutting tool shapes it.

-

Drilling: Tools create precise holes.

-

Grinding: A high-speed wheel smooths surfaces to tight tolerances.

-

EDM (Electrical Discharge Machining): Uses electrical sparks to shape hard materials.

5. Inspection and Finishing

Once machining is complete, the part undergoes quality inspection using calipers, CMMs (Coordinate Measuring Machines), or optical scanners. Depending on requirements, finishing processes such as polishing, anodizing, powder coating, heat treating, or sandblasting might be applied.

Types of CNC Machines

Modern CNC equipment comes in various configurations tailored to different tasks. Some of the most common include:

CNC Milling Machines

These use rotating tools to remove material from a stationary workpiece. They are highly versatile and can create pockets, slots, curves, and complex shapes.

CNC Lathes

Ideal for cylindrical components, lathes rotate the workpiece while shaping it with sharp cutting tools. Threads, tapers, and shafts are typical outputs.

CNC Routers

Typically used for wood, plastics, foams, and soft metals, routers are ideal for signage, furniture, and prototyping.

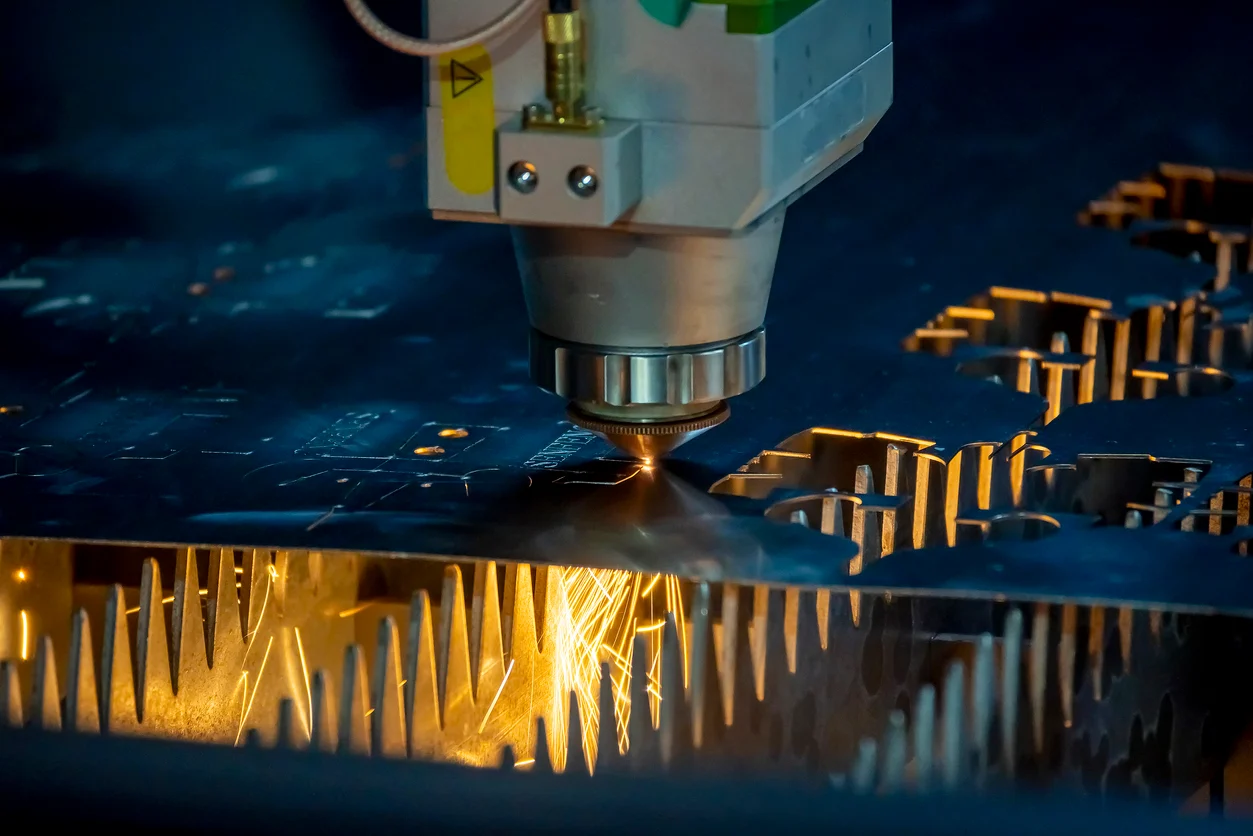

CNC Laser Cutters

These use focused laser beams to cut or engrave materials with extreme precision.

CNC Plasma Cutters

Suitable for cutting thick metals using ionized gas at high temperatures.

CNC EDM Machines

Used for extremely hard materials or shapes that traditional cutting tools cannot handle.

Each machine type has a unique purpose, but all share the hallmark precision and repeatability of CNC automation.

Materials Used in CNC Machining

One of the biggest strengths of CNC machining is its compatibility with a wide range of materials, including:

Metals:

- Aluminum

- Stainless steel

- Brass

- Titanium

- Copper

- Carbon steel

Plastics:

- ABS

- Nylon

- Acrylic

- Delrin (POM)

- Polycarbonate

- PTFE (Teflon)

Composites and Others:

- Fiberglass

- Carbon fiber sheets

- Wood and foam (for CNC routers)

This flexibility makes CNC machining suitable for countless industries and applications.

Also read, Why Are Sand Moulding Machines Important in Foundry Operations?

Benefits of CNC Machining

CNC machining remains popular for good reasons. Some of the key advantages include:

1. High Precision and Accuracy

CNC machines can produce parts with tolerance levels as tight as ±0.001 inches. This precision is crucial for industries like aerospace, automotive, medical, and defense.

2. Consistency and Repeatability

Whether producing one part or thousands, CNC machines deliver identical results, eliminating human error.

3. Speed and Efficiency

Once the programming is ready, production is rapid. CNC machines can operate continuously and at high speeds, increasing output and lowering costs.

4. Compatibility with Many Materials

Unlike some manufacturing processes that are limited to specific materials, CNC machining works with metals, plastics, composites, and more.

5. Complex Geometries Made Easy

Advanced 5-axis CNC machines can create shapes that would be impossible with manual tools.

6. Lower Labor Costs

Automation reduces dependency on manual labor, improving efficiency and profitability.

Applications of CNC Machining

CNC machining plays a vital role in multiple industries, including:

Aerospace

Turbine blades, engine components, custom fixtures, and lightweight aluminum parts.

Automotive

Engine blocks, pistons, transmission housings, and rapid prototypes.

Medical and Dental

Orthopedic implants, surgical tools, dental crowns, and prosthetics.

Electronics

Housings, heat sinks, connectors, and mechanical components.

Industrial Manufacturing

Custom tooling, production fixtures, and replacement machine parts.

Consumer Products

Furniture components, sporting goods, engraved items, and custom accessories.

Its versatility makes CNC machining indispensable across diverse manufacturing environments.

Future Trends in CNC Machining

The CNC industry continues to evolve with advancements in automation and digital manufacturing. Some emerging trends include:

Hybrid Manufacturing

Combining CNC machining with 3D printing for rapid prototyping and complex builds.

Automation and Robotics

Robotic arms now automate loading and unloading, enabling lights-out manufacturing.

AI-Driven Optimization

AI is improving toolpath planning, reducing tool wear, and predicting machine failure.

Smart Factories

CNC machines integrated into IoT networks provide real-time monitoring and predictive maintenance.

These innovations promise faster production, lower costs, and even greater precision.

Final Thoughts

CNC machining is one of the most powerful and reliable manufacturing processes available today. Whether for prototyping or mass production, it provides unmatched precision, repeatability, and versatility. As industries grow more automated and digital, CNC machining will remain at the heart of modern manufacturing driving innovation across engineering, technology, and industrial design.

FAQs

1. What is CNC machining?

CNC machining is a manufacturing process where computer-controlled machines remove material from a workpiece to create precise, complex parts. It uses programmed instructions (G-code) to automate cutting, milling, drilling, and turning operations.

2. Which materials can be used in CNC machining?

CNC machining supports a wide range of materials, including metals like aluminum, steel, titanium, and brass, as well as plastics such as ABS, nylon, acrylic, and polycarbonate.

3. What industries commonly use CNC machining?

Industries such as aerospace, automotive, medical, electronics, defense, and industrial manufacturing rely heavily on CNC machining for producing high-precision components.

Leave a Reply