Cleaning big metal things like bridges, ships, and tanks needs strong tools. You can’t use just soap and water. You need something tougher. That’s where steel grit comes in. It scrapes, scours, and clears away rust, paint, and dirt.

But to get good results, you also need to match the right grit with the right blasting machines. When you do this, your work becomes faster, smoother, and cleaner.

This guide will help you pick the best steel grit for your job. You’ll also learn how Itaichu (M) Sdn Bhd helps many workers choose smart tools for surface cleaning and preparation.

What Is Steel Grit?

Steel grit comes from crushed steel balls. The pieces look rough and sharp. They bite into surfaces and help clean or shape them. Unlike smooth sand, these sharp bits don’t slide off. They grab onto rust and strip it away.

Steel grit comes in many sizes. Each size works best for different jobs. Some scrape hard. Others brush gently. But all can help machines, tools, or metal sheets look new again.

Why Use Steel Grit?

Steel grit does a great job because it:

- Chomps through rust and thick layers

- Gives even cleaning

- Lasts longer than soft sand

- Spins well inside blasting machines

- Keeps dust low and clean-up easy

When you pick the right grit and blasting machine, you don’t waste time. You clear surfaces fast and get ready to paint or coat them.

Where Can You Use Steel Grit?

You can use steel grit in many places:

- Shipyards

- Oil and gas plants

- Metal part workshops

- Building sites

- Steel bridges and tanks

Anywhere that metal needs cleaning, steel grit can help.

How to Pick the Right Steel Grit

Not all grit works the same. You need to think about your job, your surface, and your tools. Picking the right grit can save time and keep your surface safe.

Let’s look at the main things you need to check.

1. Grit Size

Grit size tells you how big the pieces are. Big grit cuts deep. Small grit works soft and smooth.

- Tiny grit (G80–G120): These glide over the surface. Good for light cleaning.

- Medium grit (G40–G60): These scrub off paint or light rust.

- Big grit (G18–G25): These carve deep. Use them on thick coatings or heavy rust.

Remember: small number = big grit. Big number = small grit.

2. Grit Strength

Some grit breaks fast. Others stay strong for many uses. You want to match strength to your job.

- Medium-strong grit: Good for most jobs. It stays sharp and lasts long.

- Very hard grit: Cuts fast but breaks quicker. Good for hard surfaces.

The stronger the grit, the more it can scrape—but it may wear out faster too.

3. What Kind of Finish You Want

Sometimes you need a smooth finish. Sometimes you want a rough one so paint sticks better. That’s called a “profile.”

- Rough finish: Choose big grit.

- Smooth finish: Choose fine grit.

Check what your coating needs before you choose.

4. What Blasting Machine You Use

Some blasting machines like fine grit. Some work best with coarse grit. You must check your machine.

- Air blasting machines: Use small or medium grit

- Wheel blasting machines: Handle large grit easily

Itaichu (M) Sdn Bhd helps customers match the right grit to their machines so everything works well.

5. What You’re Cleaning

You must match the grit to the thing you’re cleaning.

- Steel beams or tanks: Use medium or big grit

- Small parts or tools: Use fine grit

- Concrete floors: Use coarse grit for deep cleaning

If you choose wrong, the surface might get scratched or take too long to clean.

Why the Blasting Machine Matters Too

Grit doesn’t work alone. It needs a strong helper—your blasting machine.

These machines throw grit with force so it hits the surface and scrubs it clean.

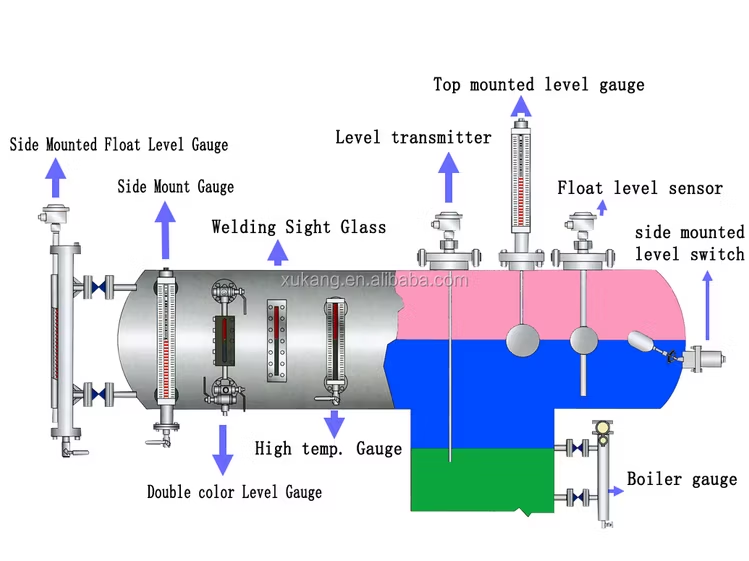

There are two main kinds:

- Air blasting machines: Blow grit using air. Great for small or tricky parts.

- Wheel blasting machines: Spin fast to fling grit. Best for big jobs like tanks or steel plates.

Your grit and machine must work together like a team. If not, the job takes longer or doesn’t turn out right.

What Happens When You Pick the Right Grit?

When you choose the best steel grit and the best machine, you:

- Clean faster

- Use less grit

- Waste less time

- Get a nice, even surface

- Save money

- Finish jobs better

This helps your business work smarter and grow stronger.

How Itaichu (M) Sdn Bhd Can Help

Itaichu (M) Sdn Bhd gives you full help with steel grit and blasting machines. We work with builders, shipyards, and factories across Malaysia.

We offer:

- Many types of steel grit

- Machines for big and small jobs

- Advice on matching grit to jobs

- Staff training for better results

- Machine care and part replacements

We don’t just sell. We teach, support, and guide.

Our Steel Grits

We stock strong, sharp, and long-lasting grit in many sizes. You get quality that works again and again.

Our Machines

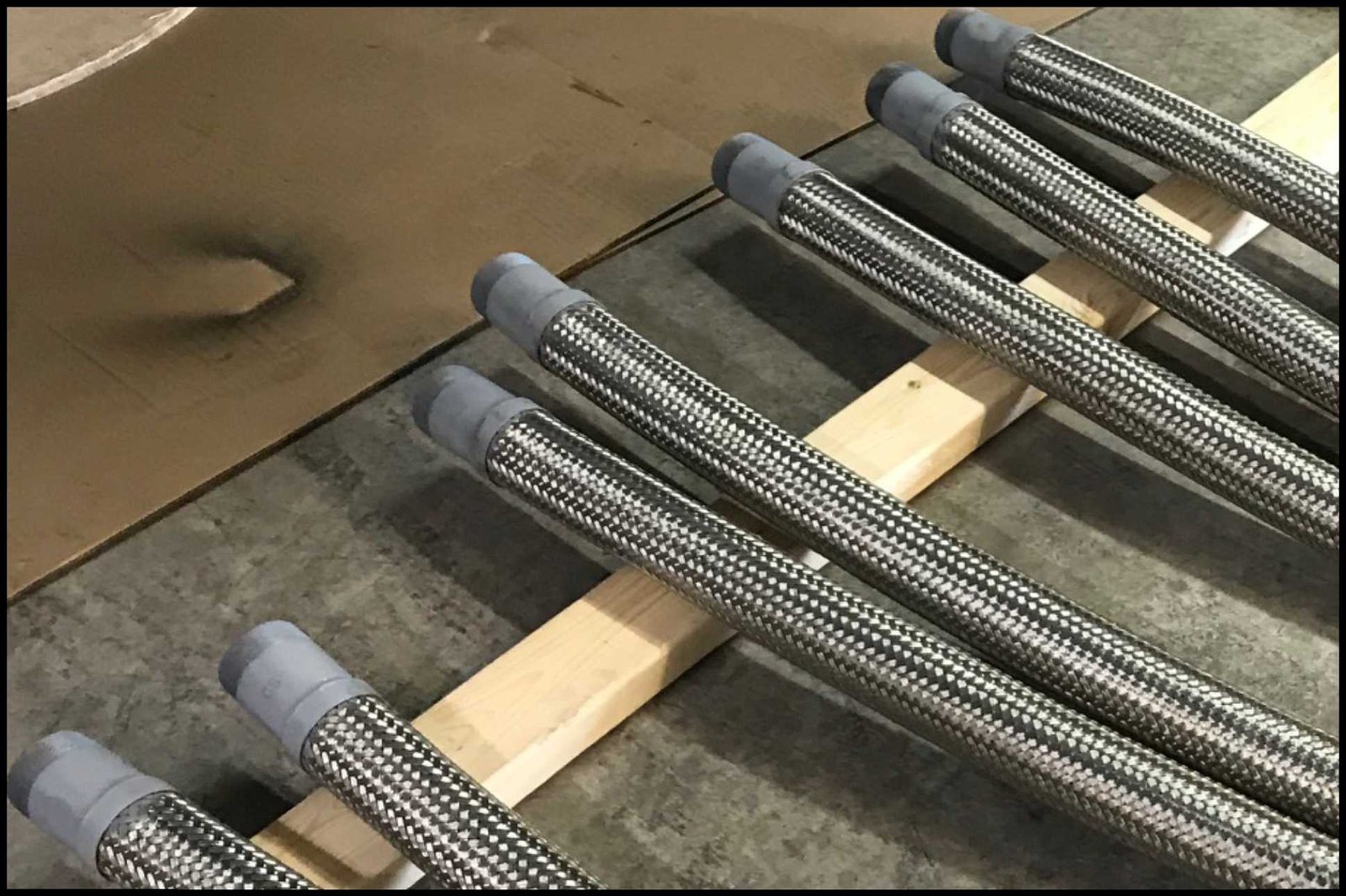

We supply air and wheel blasting machines. We also carry hoses, nozzles, and safety gear.

Our Support

Our team listens. We come to your site. We check what you need. Then we help you pick the best tools.

Tips for Better Results

Use these tips to keep your grit and machine working their best:

- Store grit in dry places: Wet grit sticks and jams

- Clean your machines often: Dust and broken grit slow things down

- Check your nozzles: Broken tips throw grit badly

- Don’t blast too hard or too soft: Find the right pressure

- Change grit when it gets too small: Old grit won’t clean well

Good care means less fixing and more blasting!

Final Words

Steel grit helps you clean, shape, and prepare surfaces fast and well. But grit is like a tool—it works best when matched to the job.

When you pair smart grit with good blasting machines, you get clean results, happy workers, and a strong finish.

And when you work with Itaichu (M) Sdn Bhd, you don’t guess—you know what works. We help you pick right, work fast, and clean smart.

FAQs

1. Can I use steel grit many times?

Yes! You can reuse it many times if you keep it clean and dry.

2. Which grit should I use for rust?

Try medium grit like G40 or G60. It cleans rust without harming the surface.

3. Can all blasting machines use steel grit?

Most can, but not all. Ask Itaichu (M) Sdn Bhd and we’ll help you pick the right one.

Leave a Reply