In the dynamic world of custom apparel and merchandise, screen printing stands as one of the most trusted and high-quality printing techniques. While digital printing technologies like DTG (Direct-to-Garment) and sublimation are gaining popularity, screen printing continues to reign supreme — especially when it comes to professional, vibrant, and long-lasting prints.

For decades, businesses, brands, and individuals have relied on screen printing in Dallas for its durability, versatility, and bold color output. Whether you’re printing t-shirts, hoodies, tote bags, or uniforms, this method ensures every piece looks premium and polished. In today’s print-on-demand landscape, screen printing remains a proven, profitable, and powerful way to deliver custom designs with exceptional quality.

What is Screen Printing?

Screen printing, also known as silk screening, is a technique where ink is pressed through a fine mesh screen onto a surface, typically fabric or paper. A stencil of the desired design is created on the screen, and each color is applied one at a time using separate screens.

This method dates back over a thousand years but has evolved dramatically thanks to modern tools and inks. Today, automated machines can print hundreds of garments per hour with remarkable precision, making it ideal for both small businesses and large-scale production.

Screen printing is particularly valued in print-on-demand (POD) businesses because it produces consistent results, even across large batches — something digital methods often struggle to achieve.

Why Screen Printing Dominates the Print-on-Demand Market

In the competitive print industry, screen printing offers distinct advantages that make it the go-to choice for professionals and online sellers alike.

1. Unmatched Durability

One of the strongest reasons people prefer screen printing is its long-lasting quality. The inks used in this process are thicker and more deeply absorbed by the fabric, resulting in prints that withstand repeated washing without cracking, fading, or peeling.

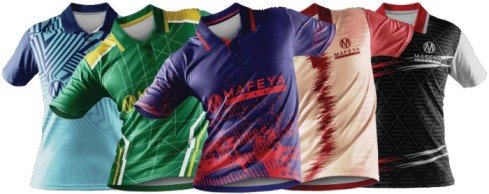

This durability makes screen printing perfect for items like sports jerseys, uniforms, and branded workwear — where longevity is key.

2. Vibrant, Eye-Catching Colors

Screen printing produces colors that truly pop. Because each ink layer is applied separately and directly onto the material, the result is a bright, saturated design that stands out. Even on dark fabrics, screen printing maintains bold color contrast without dullness.

3. Ideal for Bulk Orders

If you’re producing a large quantity of t-shirts or hoodies, screen printing is the most cost-effective option. Once the screens are prepared, each additional print takes minimal time and resources. This efficiency makes it the preferred method for bulk orders — from promotional giveaways to event merchandise.

4. Versatility Across Materials

Unlike some printing techniques that only work on specific fabrics, screen printing adapts beautifully to a wide range of surfaces, including:

-

Cotton and cotton blends

-

Polyester and performance wear

-

Canvas and tote bags

-

Paper and cardboard

-

Wood or metal signage

This versatility is why many print-on-demand providers and apparel brands still rely on screen printing to meet their customers’ diverse needs.

The Screen Printing Process – A Blend of Art and Precision

Screen printing combines craftsmanship and technology. Each design goes through several careful stages to ensure quality and consistency:

-

Design Preparation: The design is separated by color and turned into stencils, one for each ink layer.

-

Screen Coating: A mesh screen is coated with a light-sensitive emulsion.

-

Exposure and Development: The design is placed on the coated screen and exposed to UV light. The exposed areas harden, while the unexposed parts (the design) are washed away, creating a stencil.

-

Printing: The screen is positioned over the fabric, and ink is pushed through using a squeegee. This is repeated for each color layer.

-

Curing and Finishing: Once printed, the garment is heated to cure the ink, ensuring durability and wash resistance.

Each step requires precision — that’s why professional printers take great pride in perfecting their screens and setups.

Screen Printing vs. Other Printing Methods

To truly appreciate why screen printing is considered the best method for print-on-demand, it’s helpful to compare it to other popular techniques.

DTG (Direct-to-Garment) Printing

DTG is excellent for detailed, full-color images but is slower and more expensive for large batches. It also tends to fade faster than screen printing after multiple washes.

Sublimation Printing

Sublimation creates vibrant, full-coverage prints but works only on polyester and light-colored fabrics. Screen printing, in contrast, works on almost any material and color.

Heat Transfer Printing

Heat transfer is affordable for short runs, but the prints can crack or peel over time. Screen printing, on the other hand, delivers professional-grade durability.

Embroidery

While embroidery adds texture and luxury, it’s more costly and less suitable for intricate designs. Screen printing offers the same level of professionalism with a wider design range.

In short, screen printing combines the best of both worlds — quality and scalability.

How Screen Printing Powers Print-on-Demand Businesses

The rise of eCommerce and print-on-demand platforms has opened doors for entrepreneurs worldwide. Screen printing fits perfectly into this ecosystem because it allows flexibility, reliability, and cost-efficiency.

Here’s how:

-

No upfront inventory: You can print items only when an order is placed.

-

Brand customization: Offer customers the ability to personalize designs.

-

Low risk, high reward: Since production happens per order, there’s no unsold stock.

-

Scalable business model: Whether you sell 10 shirts or 10,000, screen printing can handle it.

With the help of printing partners like Printful, Printify, or local suppliers, business owners can offer screen-printed apparel through platforms like Shopify, Etsy, Amazon, and eBay, without needing expensive equipment or staff.

The Environmental Perspective

Many modern screen printing companies are moving toward eco-friendly printing by using water-based inks, organic fabrics, and sustainable production methods. These changes not only reduce environmental impact but also attract eco-conscious customers who value responsible brands.

The combination of tradition and sustainability makes screen printing a forward-thinking choice for modern businesses.

Marketing Your Screen-Printed Products

Having great prints is only part of the equation. To make your screen printing business successful, marketing plays a crucial role. Here are a few proven strategies:

-

Social Media Marketing: Share design videos, customer photos, and limited-edition launches on Instagram, Facebook, and TikTok.

-

SEO and Blogging: Use keywords like custom t-shirt printing, screen printed apparel, and print on demand to attract organic traffic.

-

Collaborations: Partner with local artists, influencers, or small brands to create exclusive collections.

-

Email Campaigns: Keep customers engaged with new releases and discounts.

-

Customer Reviews: Encourage satisfied buyers to share photos or testimonials — this builds trust and credibility.

With consistency and creativity, your screen printing business can grow from a small side hustle to a full-fledged online brand.

Final Thoughts

In an era filled with digital solutions, screen printing continues to prove that classic methods never go out of style. It offers the perfect combination of durability, affordability, and artistry — making it the ideal choice for both individual creators and established brands.

Whether you’re printing for fun, fashion, or business, screen printing remains the gold standard for print-on-demand. Its ability to produce vibrant, long-lasting designs on virtually any material gives it an edge that no other technique can match.

So, if you’re planning to start your own custom apparel line or expand your printing services, look no further than screen printing — a time-tested method that delivers excellence with every print.

Leave a Reply