Mountable levels are a crucial component in various industries, from construction to engineering. They ensure accuracy, stability, and alignment in multiple projects. Whether you are a professional or a hobbyist, understanding mountable levels can significantly enhance the quality of your work. These tools allow users to measure surfaces, angles, and gradients efficiently, reducing errors and saving time.

In this article, we will explore different types of mountable levels, their applications, benefits, and how to choose the right one for your needs. For more technical specifications and product details, you can check mountable levels for comprehensive insights.

What Are Mountable Levels?

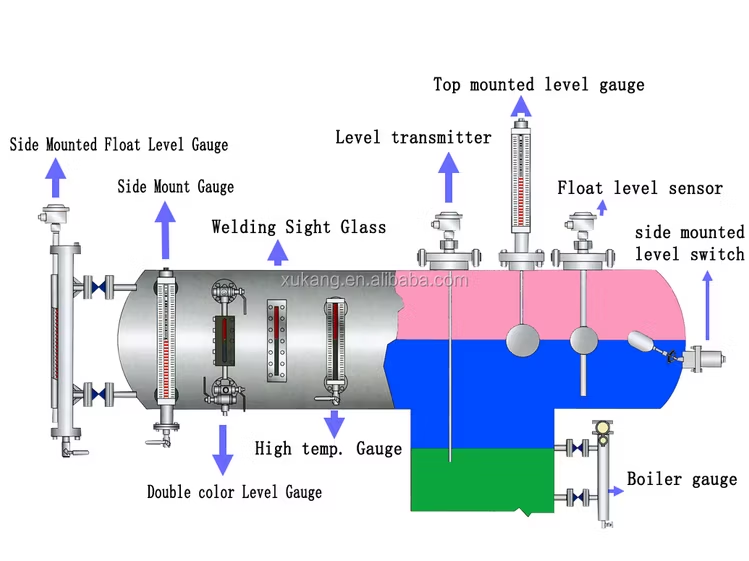

Mountable levels are devices designed to measure the horizontal or vertical alignment of a surface. They often consist of a bubble vial or digital sensors to indicate precision. Traditionally, these tools have been used in carpentry, masonry, and metalwork. Modern versions now include electronic and laser levels that provide higher accuracy and ease of use.

The term “mountable” refers to their capability to be fixed on surfaces or equipment. Mountable levels can attach to machinery, scaffolding, or workbenches, allowing continuous measurement without manual handling. This stability enhances accuracy and makes repetitive tasks easier.

Types of Mountable Levels

Mountable levels vary in design, material, and functionality. Selecting the right type depends on the specific task and working environment.

1. Spirit Levels

Spirit levels, also called bubble levels, are among the oldest and most common tools. They consist of a liquid-filled vial with an air bubble. When the bubble aligns between markings, the surface is level. Spirit levels can be handheld or mounted using brackets for stationary measurements.

2. Laser Levels

Laser levels project a straight line over a distance, allowing for precise alignment over large areas. These are popular in construction and interior design. Mountable laser levels often come with tripods or magnetic bases for secure attachment, reducing human error.

3. Digital Levels

Digital mountable levels display angles and inclines electronically. They are highly accurate and often feature data logging for complex projects. Many digital models offer multiple mounting options, including clamps and brackets, for long-term measurements.

Key Applications of Mountable Levels

Mountable levels serve multiple purposes across industries. Their versatility makes them indispensable in both professional and DIY projects.

Construction and Carpentry

In construction, precision is crucial. Mountable levels ensure walls, floors, and ceilings are perfectly aligned. They reduce costly mistakes and enhance structural integrity. Carpenters often use these tools to align cabinets, doors, and frames.

Metal Fabrication

Metalworkers rely on mountable levels for machinery setup and welding. Proper alignment prevents structural failures and improves the longevity of fabricated components. Mountable laser levels are particularly useful for aligning large metal sheets or pipelines.

Surveying and Civil Engineering

Civil engineers use mountable levels to measure slopes, gradients, and terrains. Accurate leveling ensures roads, bridges, and drainage systems function correctly. Survey-grade mountable levels are essential for large-scale projects where precision is non-negotiable.

DIY Projects

Even hobbyists benefit from mountable levels. Installing shelves, assembling furniture, or laying tiles becomes simpler with accurate leveling tools. Their mountable nature allows hands-free operation, making home projects safer and more efficient.

Advantages of Mountable Levels

Mountable levels offer distinct advantages over traditional handheld tools. Their stability, accuracy, and ease of use make them preferable in many scenarios.

Enhanced Accuracy

By attaching directly to surfaces or equipment, mountable levels minimize human error. This feature ensures measurements remain consistent, even in repetitive tasks. Digital mountable levels further increase precision by providing exact numerical readings.

Time Efficiency

Mountable levels save time by allowing continuous measurement without frequent repositioning. This efficiency is critical in large-scale projects where manual handling could delay progress.

Safety Improvements

Mountable levels reduce the need for awkward positioning or climbing to measure surfaces manually. Workers can achieve precise results while minimizing physical strain and risk of injury.

Versatility

Most mountable levels come with adjustable brackets, magnetic bases, or clamps. This versatility enables usage on diverse surfaces, including walls, floors, machinery, and outdoor terrain.

Choosing the Right Mountable Level

Selecting the right mountable level requires consideration of multiple factors. Choosing wisely ensures optimal performance and durability.

Accuracy Requirements

Evaluate the precision needed for your project. For basic household tasks, a standard spirit level may suffice. For industrial applications, digital or laser mountable levels provide higher accuracy.

Mounting Options

Consider where and how the level will be mounted. Magnetic bases are ideal for steel surfaces, while clamps work for irregular surfaces. Some models offer tripods for flexible positioning.

Durability and Build Quality

Mountable levels should withstand the working environment. Look for materials resistant to corrosion, impact, or temperature variations. Aluminum and reinforced plastic are common choices for professional tools.

Additional Features

Modern mountable levels may include laser projection, angle readouts, digital displays, or Bluetooth connectivity. Determine which features are essential to your work to avoid overspending on unnecessary functions.

Maintenance Tips for Mountable Levels

Proper maintenance ensures long-term performance and reliability.

-

Clean Regularly: Dust, dirt, and debris can affect accuracy. Wipe the level after each use.

-

Check Calibration: Periodically verify calibration against a known level surface. Recalibrate if readings are off.

-

Store Safely: Keep the level in a protective case to prevent damage from drops or impacts.

-

Avoid Excessive Force: Handle with care. Mountable levels are precise instruments, and rough handling can misalign internal components.

Common Mistakes to Avoid

Even experienced users sometimes misuse mountable levels. Awareness of these mistakes can save time and resources.

-

Improper Mounting: Ensure the level is securely attached. Loose mounts can cause inaccurate readings.

-

Ignoring Calibration: Skipping calibration checks can result in cumulative errors over time.

-

Overlooking Environmental Factors: Temperature and vibration can affect sensitive digital levels. Always account for environmental conditions.

-

Neglecting Regular Maintenance: Failing to clean or inspect the level reduces its lifespan and reliability.

Future Trends in Mountable Levels

Technology continues to improve mountable levels, offering increased efficiency and precision.

-

Integration with Smart Devices: Some modern levels sync with smartphones or tablets for real-time monitoring and recording.

-

Enhanced Laser Technology: New lasers provide brighter, longer-range, and more stable projections.

-

AI-Assisted Measurement: Artificial intelligence may soon assist in automatically adjusting and correcting alignments in real-time.

-

Eco-Friendly Materials: Manufacturers are exploring sustainable materials to reduce environmental impact without sacrificing durability.

Conclusion

Mountable levels are essential tools for anyone requiring precision, whether in professional industries or home projects. Their ability to attach securely to surfaces, combined with advanced features, provides unmatched accuracy, safety, and efficiency. By understanding the types, applications, and maintenance practices, users can maximize the benefits of these tools. Choosing the right mountable level depends on your accuracy needs, mounting options, and project type. Investing in a high-quality mountable level ensures long-term reliability, saving both time and money.

Leave a Reply