The Fundamentals of Liquid-Liquid Extraction

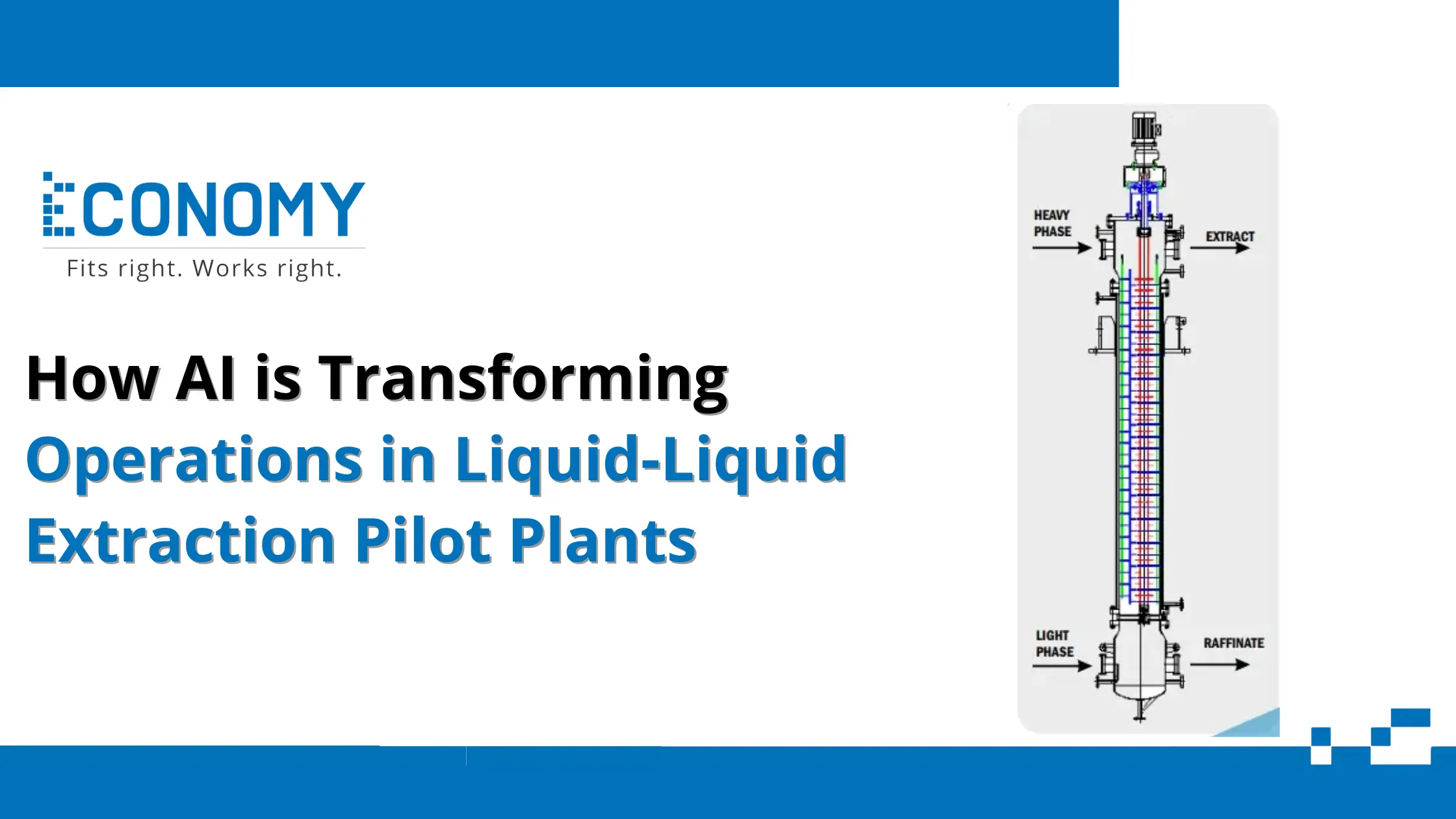

Liquid-Liquid Extraction (LLE) is a key separation technique used in industries such as pharmaceuticals, chemicals, biotechnology, and environmental engineering. It involves the transfer of a solute from one liquid phase into another immiscible liquid phase, typically an organic solvent and an aqueous solution. The process depends on the solubility of the components in each phase and their mutual immiscibility.

In industrial pilot plants, LLE plays a vital role in scaling up laboratory processes to production scale. Engineers test and refine parameters like solvent ratio, temperature, mixing intensity, and contact time to achieve optimal extraction efficiency. However, managing these variables manually can be challenging. Traditional methods rely heavily on operator experience and experimental trials, which can be time-consuming and less precise. This is where Artificial Intelligence (AI) is making a significant impact, revolutionizing the way extraction processes are monitored, optimized, and controlled.

Artificial Intelligence in Extraction Process and Its Role

Artificial Intelligence refers to the ability of machines to perform tasks that typically require human intelligence, such as learning, decision-making, and problem-solving. In the context of Liquid-Liquid Extraction, AI helps automate and optimize complex process parameters by analyzing large sets of data collected from sensors and control systems.

Through advanced algorithms such as machine learning (ML) and neural networks, AI can model intricate relationships between operating conditions and extraction performance. Instead of relying solely on empirical testing, AI systems learn from past data to predict outcomes like phase separation time, extraction yield, or impurity removal efficiency.

Moreover, real-time AI integration allows dynamic process control. For instance, when fluctuations occur in feed composition or temperature, AI-driven control systems can automatically adjust solvent flow rates or mixing speeds to maintain optimal performance. The introduction of digital twins—virtual simulations of pilot plant operations—enables engineers to experiment digitally, minimizing trial-and-error in real setups. These AI-enhanced simulations can predict performance under various conditions, helping achieve efficient design, faster scale-up, and reduced waste.

Benefits of Executing Artificial Intelligence Innovation

The incorporation of Artificial Intelligence in Liquid-Liquid Extraction pilot plants brings multiple operational and economic advantages:

-

Enhanced Process Optimization:

AI algorithms can identify optimal conditions for extraction processes, minimizing the need for repeated manual adjustments. This leads to higher purity and better yield with minimal resource consumption. -

Predictive Maintenance:

By continuously monitoring equipment parameters like temperature, vibration, or pressure, AI can detect early signs of mechanical wear or failure. This predictive capability reduces unplanned downtime and extends equipment lifespan. -

Improved Safety and Consistency:

AI systems ensure that critical limits are not breached. They maintain process stability and automatically correct deviations, reducing the risk of accidents and inconsistent product quality. -

Data-Driven Decision-Making:

Instead of relying on assumptions or manual logs, engineers can base decisions on AI-generated insights, resulting in more reliable and precise process adjustments. -

Reduced Operational Costs:

With fewer manual interventions, optimized energy consumption, and extended maintenance cycles, AI-driven operations lower overall operating costs while improving throughput. -

Faster Process Development:

AI accelerates experimentation by predicting the most effective extraction conditions, reducing the time required for pilot-scale studies before full-scale production.

Contextual Analyses of Artificial Intelligence Execution in Extraction Frameworks

Several industries have successfully implemented AI in extraction operations, demonstrating its transformative impact:

-

Pharmaceutical Industry:

In pilot plants for API (Active Pharmaceutical Ingredient) production, AI-based models have been used to optimize solvent selection and mixing parameters. Machine learning algorithms analyze prior experimental data to predict phase behavior and select conditions that maximize purity and yield. -

Chemical Manufacturing:

Companies have employed AI to monitor multi-stage extraction processes in chemical synthesis. Neural networks integrated with real-time sensors allow continuous process optimization, significantly reducing product variability. -

Environmental Engineering:

AI has been applied to optimize the removal of pollutants from wastewater using solvent extraction. By predicting solute distribution coefficients and extraction efficiency, AI models enable effective treatment with minimal solvent consumption.

These real-world applications highlight how AI enhances accuracy, scalability, and environmental sustainability in extraction operations. Pilot plants adopting AI systems have reported reduced cycle times, improved reproducibility, and greater control over critical process variables.

Overcoming Barriers to AI Adoption in Pilot Plants

Despite its numerous benefits, implementing AI in pilot plant environments presents several challenges:

-

Data Availability and Quality:

AI systems rely on large, high-quality datasets to train accurate models. Many pilot plants still lack sufficient data collection infrastructure, leading to inconsistent inputs. -

Integration with Legacy Systems:

Older pilot plants often use traditional control systems that are not easily compatible with modern AI solutions, making integration complex and costly. -

High Implementation Costs:

Initial investment in sensors, software, and skilled personnel can be significant, especially for small- to medium-sized facilities. -

Workforce Adaptation:

Introducing AI-driven automation requires upskilling operators and engineers. Resistance to adopting new technologies can slow down implementation. -

Cybersecurity Concerns:

Increased digital connectivity also exposes systems to potential cyber threats, making secure data handling and network protection essential.

To overcome these obstacles, a phased approach works best—starting with limited AI applications such as predictive maintenance or parameter optimization and gradually expanding to full-scale process automation. Collaboration between data scientists and process engineers is crucial to align AI models with real-world plant conditions.

What Lies Ahead for Simulated Intelligence in Pilot Plant Tasks?

The future of AI in Liquid-Liquid Extraction pilot plants looks promising. As Industry 4.0 technologies continue to evolve, AI will integrate more deeply with Internet of Things (IoT) sensors, edge computing, and cloud-based analytics to enable seamless, real-time process control.

We can expect the rise of self-learning pilot plants, where AI continuously adapts to changing process dynamics and autonomously adjusts operational parameters to maintain peak performance. The combination of AI with automation and robotics will further reduce human intervention, leading to safer, more consistent, and cost-efficient pilot operations.

Moreover, AI-driven sustainability models will help optimize solvent usage, minimize waste generation, and lower the environmental footprint of extraction processes—aligning with global goals for greener manufacturing.

Final Words

Artificial Intelligence is rapidly transforming Liquid-Liquid Extraction pilot plants by introducing precision, adaptability, and data-driven control into traditionally manual processes. From predictive analytics to real-time optimization, AI empowers engineers to achieve higher yields, reduced downtime, and greater operational safety.

Though challenges such as cost, data limitations, and workforce readiness remain, the long-term advantages are undeniable. As industries embrace digital transformation, AI will play a central role in shaping the next generation of intelligent, automated, and sustainable pilot plant operations.

Leave a Reply