In today’s rapidly evolving field of vacuum engineering, precision and material quality determine how efficiently systems operate. One of the most vital yet often overlooked components is th — a cornerstone for ensuring leak-tight seals in both research and industrial applications. Whether used in physics laboratories, semiconductor plants, or coating facilities, this simple yet effective component forms the backbone of a reliable vacuum environment.

At Vacuum Chambers, we understand that great design—whether in interiors or high-performance equipment—comes down to craftsmanship and precision. That same philosophy applies to the engineering of high-vacuum systems. When each element, from the flange to the chamber body, is carefully selected and perfectly fitted, the system runs smoother, lasts longer, and performs at its best.

Why the Flange Matters

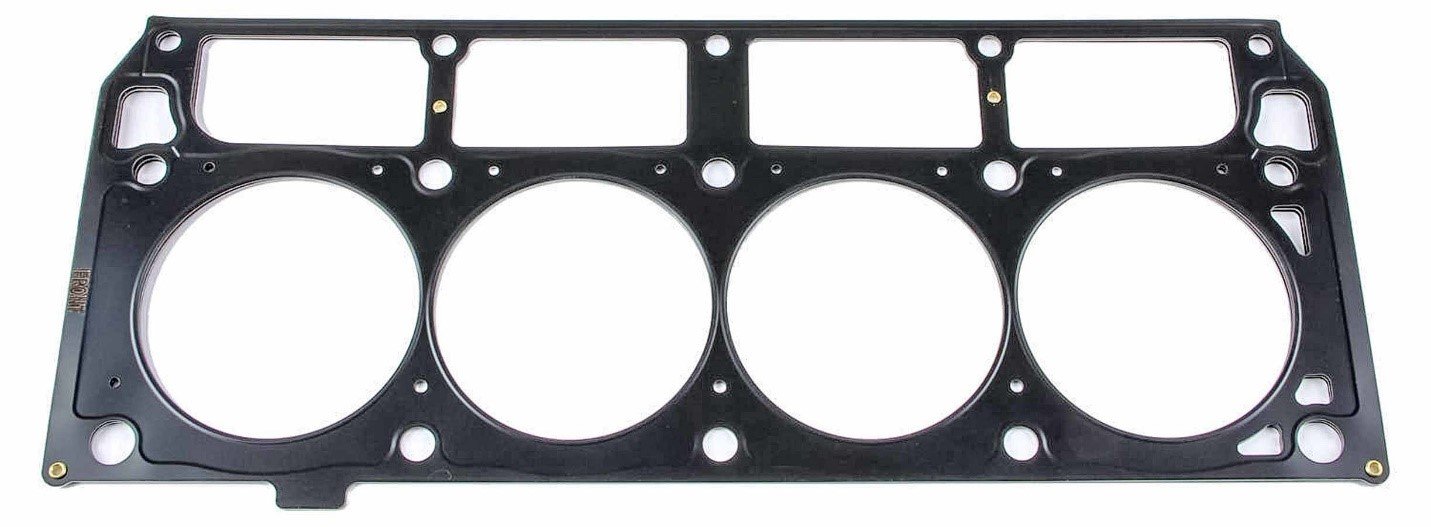

The Conflat flange is not just another fitting; it’s the key interface between your vacuum chamber and the external world. Built typically from stainless steel or aluminum, it uses a knife-edge design that compresses a copper gasket to create a permanent, ultra-tight metal seal. This design enables the system to achieve pressures as low as 10⁻¹³ Torr, essential for ultra-high vacuum operations.

Because these flanges are symmetrical (meaning two identical parts mate together), they simplify assembly and minimize the risk of mismatch. When installed correctly—with precise torque, surface cleanliness, and the right gasket—the result is a dependable and long-lasting seal. A poor seal, on the other hand, can lead to pressure instability and contamination, severely affecting results or product quality.

In high-vacuum environments, attention to detail makes all the difference. Even a microscopic particle trapped between sealing surfaces can compromise performance. That’s why expert installation and proper material handling are critical in maintaining chamber integrity.

Modern Trends in Vacuum Chamber Design

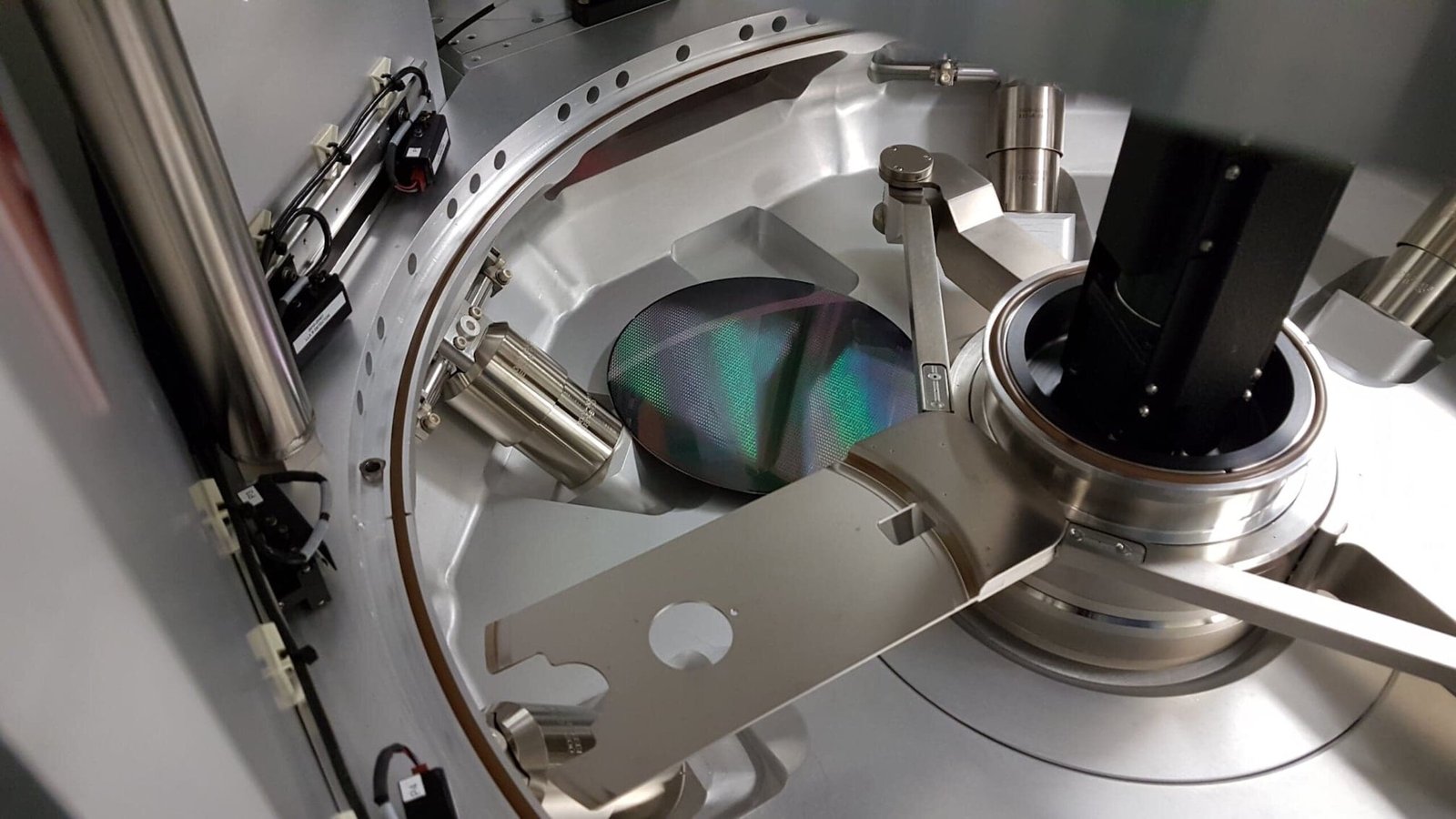

Vacuum technology has progressed far beyond the simple sealed boxes of earlier decades. Today’s systems are designed for performance, energy efficiency, and adaptability. The modern high vacuum chamber is a precision-built structure capable of supporting advanced applications ranging from material science to aerospace research.

In 2025, we’re seeing strong demand for modular and custom solutions. Laboratories and manufacturing units alike want chambers tailored to their specific research or production needs. Features such as integrated viewing ports, multi-axis feedthroughs, and temperature-controlled walls are now standard options.

At the same time, automation and smart monitoring have become essential. Systems can now regulate pressure, gas flow, and temperature automatically while providing real-time data analysis. This advancement not only boosts productivity but also extends the service life of the chamber by preventing operational errors.

Small Vacuum Chambers: Compact but Capable

Not every setup requires a large installation. Many laboratories prefer small vacuum chambers for testing, prototyping, or educational use. Despite their size, these units can still achieve high or even ultra-high vacuum levels when properly engineered. Their advantage lies in portability, cost efficiency, and reduced pump-down time.

When selecting a small chamber, factors like material purity, weld quality, and interior finishing are crucial. The smaller the space, the greater the effect of contaminants and surface irregularities. Therefore, even compact systems must be built with the same level of precision as larger industrial ones.

These smaller chambers are becoming increasingly popular for specialized research, such as thin-film deposition, sensor testing, and vacuum packaging of sensitive components.

Key Construction Considerations

Building a vacuum chamber requires more than just mechanical skill—it’s a process rooted in material science and precision engineering. Here are some essentials:

- Material Choice: Stainless steel remains the most popular choice due to its low outgassing and resistance to corrosion. Aluminum, while lighter, demands meticulous surface treatment and cleaning.

- Surface Finishing: A smooth internal finish reduces contamination and enhances vacuum quality. Polishing and ultrasonic cleaning are common preparation steps.

- Port Design: Each port and connection point must be carefully positioned to optimize gas flow and allow maintenance access without disrupting the vacuum environment.

- Seal Quality: A strong seal is achieved not just through the right gasket but also through correct alignment, torque, and cleanliness during assembly.

- Testing and Validation: Leak detection, bake-outs, and pressure tests are essential before a chamber is deemed production-ready.

This level of attention ensures that every component—from the Conflat flange to the chamber body—works harmoniously for peak performance.

Partnering With the Right Experts

The market for vacuum technology is competitive, and not all suppliers offer the same level of precision or service. Choosing an experienced Vacuum Chamber Manufacturer means securing not just a product but a long-term technical partnership. Reliable manufacturers provide design consultations, documentation for materials and welds, and ongoing support for maintenance or upgrades.

The same way homeowners trust Vacuum Chamber for professional craftsmanship and aesthetic precision, researchers and engineers should expect the same level of care in vacuum system design. Expert guidance ensures your system is customized for your application, compliant with safety standards, and built for durability.

Applications Across Industries

Vacuum technology supports an array of industries:

- Semiconductors: Used for etching, deposition, and testing under controlled environments.

- Aerospace: Chambers simulate extreme pressure and temperature conditions.

- Material Science: Essential for studying thin films, surface reactions, and atomic-scale phenomena.

- Medical Equipment: Used in sterilization, coating implants, and manufacturing sensitive devices.

Each application demands precision, and that’s why customization is key. What works for one sector might not be ideal for another. The right manufacturer understands this distinction and tailors each chamber accordingly.

Conclusion:

Vacuum engineering represents the perfect blend of science and craftsmanship. Every gasket, weld, and bolt contributes to the overall integrity of the system.

Working with an experienced Vacuum Chamber Manufacturer ensures that you’re investing in reliability, performance, and safety. These chambers are not just mechanical vessels—they’re the foundation of discovery and innovation.

Leave a Reply