Motorsport cars and heavy-duty trucks are driven harder and run hotter than other kinds of machinery. This is where Multi Layer Steel Gaskets (MLS) come into their own. Designed to withstand the highest pressures and temperatures, those gaskets provide a reliable seal between any components inside an engine. It is therefore crucial that the integrity of these gaskets be checked periodically enough to help ensure long-term engine performance for truck operators, fleet managers, and industrial users alike. Our company, NA Diesel is focused on providing engine parts that meet OEM standards single cylinder and Cummins 14 engine parts for industrial and fleet markets.

Why Multi Layer Steel Gaskets Are Essential

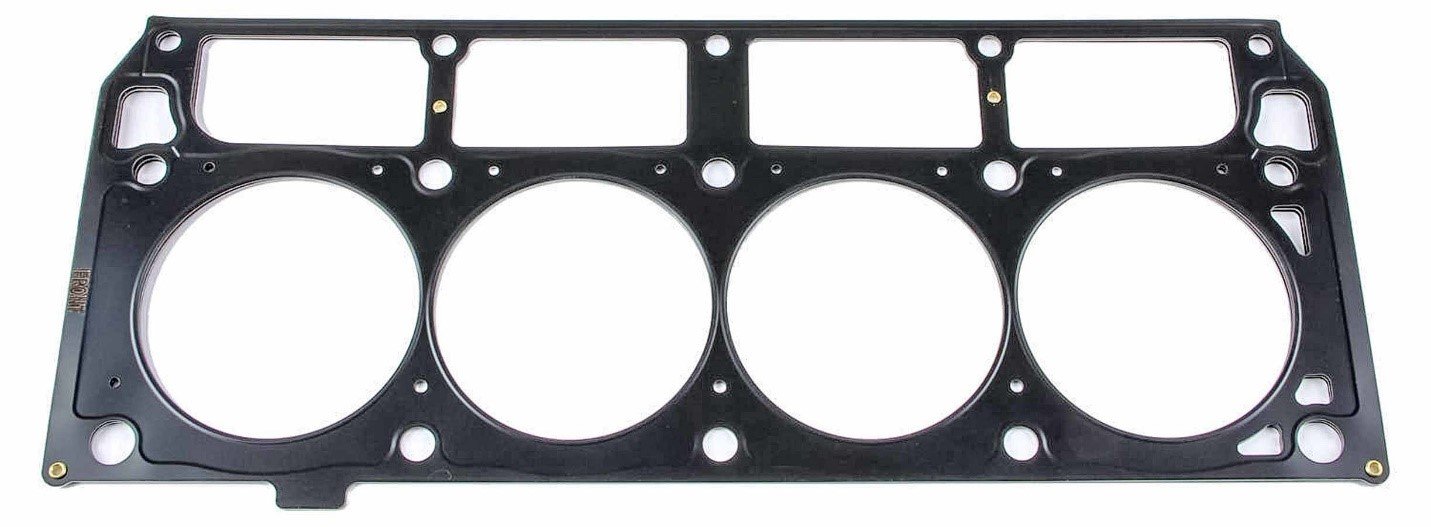

The Multi Layer Steel (MLS )-gaskets are consists of several layers of steel, sometimes with a special coating. Unlike composite gaskets, the following benefits are provided by MLS gaskets:

Long service life: it is possible to resist repeated heating and cooling cycles without deforming.

Outstanding sealing performance: The gaskets prevent coolant oil and combustion gas leaks that would harm engine performance

Compatibility with modern engines: MLS gaskets are suitable for high-performance diesel engines which operate under high compression ratios.

Spending money on high-quality MLS gaskets minimizes the risk of costly engine failures, and ensures effective operation in all sorts of heavy-duty applications.

Understanding Common Engine Applications

Many of the commercial and industrial vehicles, which will not allow any kind of failure, have heavy-duty engines. The N14 cummins engine is a favourite to go for when it comes time to equip trucks build earth-moving and industrial machinery. These engines require precision components and particularly fit for the job are the MLS gaskets, which provide optimal sealing between the cylinder head and the engine block.

The company guarantees that all its parts undergo strict quality checks to make sure they meet sound engineering practices.

Choosing The Right Gasket

A few thoughts on which MLS gasket should be chosen to suit particular requirements are given below, given extensive variations in parameters ranging from engine type and model through material quality, thickness & number of layers etc. In general the advice from manufacturers should be sought for installation of any particular gasket.

Type and model of engine: Not all gaskets are universal, so check that your chosen one is compatible with the engine in use – be it a Cummins N14 or Caterpillar.

Quality of material: Choose MLS gaskets made from high-quality stainless steel & with coatings suited to match this kind. Those are resistant to corrosion.

Thickness and number of layers: The number of layers affects the compression and sealing. It is vital to refer to the manufacturers’ specifications for the most suitable option.

Quality aids fitting: Even a good gasket can be rendered ineffective if it is not fitted accurately. So follow the torque settings and ensure that everything’s in line.

Installation by Professionals: As a result, the gaskets work reliably for the life of your engine.

Maintenance Tips For Long Engine Life Coolant and oil levels

Check coolant and oil levels regularly. Running low on either fluid increases the risk of overheating, which may lead to leaking gaskets.

The engine should be checked regularly: Look out for signs of leaks or ordinary-looking engine conditions which are different from everyday experience. It’s best to catch the problem early, in other words before things get expensive!

Observe the manufacturer’s recommended maintenance intervals: For engines such as the N14 Cummins, it’s important to keep to the scheduled service times in order to optimize lifetime performance and efficient running.

Employ quality replacement parts: For now, it may save money to substitute crummier parts. Nonetheless doing this usually leads to a costly repair.

Conclusion:

Selecting high-quality gaskets is not only a wise investment for anyone responsible for taking care of their own engine but can also pay off handsomely over time when it is done right and keeps things running smoothly. Not everything needs to be available “off the shelf” from your normal chip engineering company (though we sure won’t complain if that happens); wherein people understand how everything fits together in perfect synchrony—and those who will be glad they did so when it’s time to race your machine competitively again.

For businesses and vehicle operators looking for reliable engine solutions, NA Diesel supplies both Parts for Caterpillar Engines and know-how to meet the challenges. In terms of component quality and correct installation, this approach minimizes downtime, prevents maintenance bills from mounting up, and keeps your equipment performing at its best.

Leave a Reply