In commercial buildings, industrial facilities, and even high-end residential systems,

air handlers are the unsung heroes of indoor climate control. They regulate airflow, ensure proper ventilation, and maintain temperature consistency. But while performance and reliability are essential, energy efficiency has become the defining metric of modern HVAC systems.

So, how much power does an air handler really use—and what can be done to reduce it without sacrificing comfort or performance? Let’s break it down.

Understanding Air Handler Energy Use

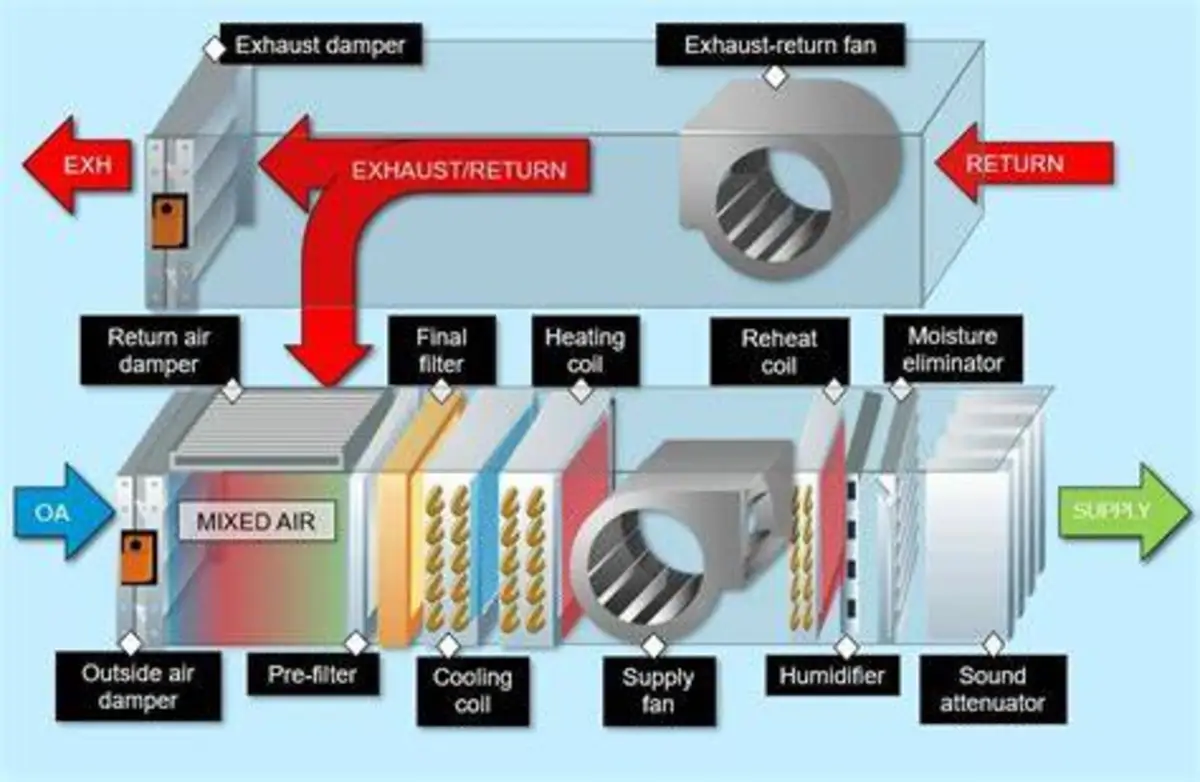

An air handler’s energy consumption depends on several interconnected factors: motor type, fan design, control strategy, and system load. At its core, the unit’s main energy draw comes from two sources:

The fan motor – responsible for circulating air through ducts, filters, and coils.

Heating or cooling components – if integrated, these add significant energy demand.

A typical commercial air handling unit (AHU) can consume anywhere from 2 kW to over 50 kW, depending on system size, airflow rate, and static pressure. In large-scale applications—like data centers or hospitals—air handler systems can account for 30–50% of a building’s total HVAC energy use.

Key Factors That Drive Energy Consumption

1. Fan Efficiency

Fan systems are often the biggest opportunity for energy savings. The efficiency of fans is influenced by:

Impeller design (forward-curved vs. backward-curved blades)

Airflow path resistance

System balancing and duct layout

High-efficiency, EC (electronically commutated) or VFD (variable frequency drive) motors can drastically reduce fan power consumption—sometimes by 20–40% compared to fixed-speed motors.

2. Filtration

Filters are critical for indoor air quality, but they create resistance to airflow. The higher the filter’s MERV rating, the greater the pressure drop and the harder the fan must work. Smart filter management—balancing filtration effectiveness with airflow efficiency—is key to controlling energy costs.

3. Coil and Heat Exchange Performance

Coils transfer heat between air and refrigerant or water. Dirty coils, improper airflow, or mismatched coil sizes reduce heat exchange efficiency, forcing longer run times and higher energy draw.

4. Control Systems

Modern building management systems (BMS) can optimize air handler performance by adjusting fan speeds, temperatures, and airflows in real time based on occupancy and demand. Without intelligent controls, systems often run at full capacity unnecessarily—wasting energy.

Calculating Power Use: A Simplified Approach

To get a quick estimate of air handler energy use, you can use this formula:

Power (kW)

=

Airflow (CFM)

×

Total Pressure (in. w.g.)

6356

×

Fan Efficiency

Power (kW)=

6356×Fan Efficiency

Airflow (CFM)×Total Pressure (in. w.g.)

Then, to find annual energy consumption (kWh):

kWh per year

=

Power (kW)

×

Operating Hours per Year

kWh per year=Power (kW)×Operating Hours per Year

For example:

A fan delivering 10,000 CFM at 4 in. w.g. total pressure and 60% efficiency, operating 4,000 hours per year, would use roughly 4,200 kWh annually.

Multiply this by multiple units across a building, and the energy use becomes substantial—making even small efficiency gains highly valuable.

Reducing Air Handler Energy Consumption

Upgrade to High-Efficiency Motors

Switching from a standard induction motor to a VFD or EC motor can yield immediate savings. Variable-speed operation allows fans to run only as hard as needed to maintain airflow targets.

Implement Demand-Controlled Ventilation

Instead of running constantly at a fixed volume, air handlers equipped with CO₂ sensors or occupancy controls adjust ventilation dynamically, cutting energy use during low-demand periods.

Regular Maintenance

Dirty filters, worn belts, and coil fouling all add resistance and drive up power draw. A well-maintained air handler can run up to 15% more efficiently than a neglected one.

System Integration

Integrating air handlers with energy recovery systems—such as heat wheels or plate exchangers—allows facilities to reclaim up to 70% of exhaust air energy, reducing heating and cooling loads.

Innovative Technologies Shaping the Future

Manufacturers are introducing smart air handlers that combine sensors, analytics, and automation. These systems continuously monitor performance data, self-adjust for optimal efficiency, and provide predictive maintenance alerts.

Additionally, next-generation fan technologies—like plug fans and backward-curved impellers—are improving static efficiency while reducing noise and vibration. The result: lower energy use, extended equipment life, and improved occupant comfort.

The Bottom Line

Air handler energy efficiency is no longer just a design consideration—it’s a business imperative. Energy costs are rising globally, and sustainability targets are tightening. Investing in efficient equipment, smart controls, and proper maintenance can deliver significant savings over the system’s lifecycle.

When selecting or upgrading an air handling system, prioritize:

- Energy-efficient fan and motor technologies

- Smart control integration

- Proper sizing and filtration balance

By focusing on these factors, organizations can ensure their Air Handler Energy use aligns with both operational efficiency and environmental responsibility—without compromising performance or comfort.

The Smart Way to Use a 1/2 PK Air Conditioner Efficiently

AC 1/2 PK (roughly 0.5 horsepower) is one of the most popular AC sizes for small rooms or personal spaces. Compact yet powerful, it’s perfect for bedrooms, offices, or small apartments. However, to truly get the best performance from it, smart usage is key.

First, match the AC capacity to your room size. AC 1/2 PK unit works best for rooms around 9–12 square meters. If the space is too large, the AC will struggle to cool efficiently, wasting energy and shortening its lifespan.

Next, maintain good insulation. Keep doors and windows closed while the AC is on, and use curtains or blinds to block direct sunlight. This helps the unit cool faster without working overtime.

Temperature setting matters too. Many users set their AC to the lowest temperature, thinking it will cool faster—but that’s a myth. Setting it between 24–26°C provides a balance between comfort and energy efficiency.

Don’t forget regular maintenance. Clean or replace filters every month to ensure smooth airflow and prevent dust buildup that can reduce cooling power.

Lastly, use the timer feature. Set it to turn off automatically during the night or when you’re away. Small habits like this can lower your electricity bill significantly.

In short, 1/2 PK Air Conditioner can be a cool companion—literally and financially—when used wisely. Treat it right, and it’ll keep you comfortable for years while keeping your energy costs low.

More info about AC 1/2 PK visit website acjakarta.com

Leave a Reply