In modern geotechnical engineering, the self drilling anchor system has emerged as a game-changing solution for soil stabilization, slope protection, tunnel support, and foundation reinforcement. Its adaptability to complex ground conditions makes it an efficient and reliable choice for engineers. One critical component that ensures the long-term performance and stability of this system is grouting. Without proper grouting, even the most advanced self drilling anchor system can fail to achieve its full potential.

This guide explores everything you need to know about grouting in self drilling anchor systems, from its purpose and types to best practices and common challenges. If you’re working in construction, civil engineering, or mining, understanding the grouting process is essential for the success of your anchoring solution.

What is a Self Drilling Anchor System?

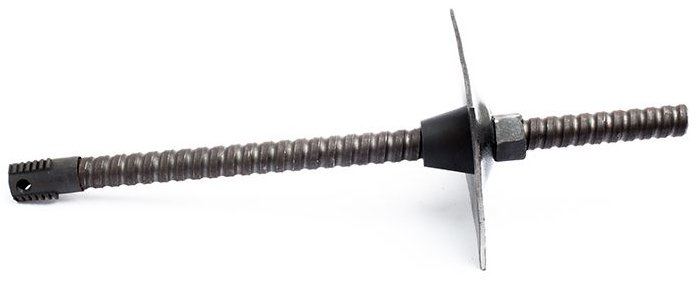

Before diving into grouting, it’s important to understand what a self drilling anchor system is. This system is a combination of drilling, anchoring, and grouting, typically used in unstable or loose ground where traditional anchoring methods are not feasible.

The self drilling anchor system consists of a hollow, threaded steel rod with a sacrificial drill bit at the tip. The unique feature is that the anchor bar serves both as the drill rod and the final anchor body. As the anchor is drilled into the ground, grout is injected through the hollow bar, filling the borehole and securing the anchor in place.

One of the leading names in advanced anchoring solutions, Argentium, has refined this technology to deliver maximum load-bearing capacity even in the most unpredictable ground conditions.

Why is Grouting Important in Self Drilling Anchor Systems?

Grouting is not just an accessory step, it’s the lifeline of the self drilling anchor system. Here’s why:

- Stabilization: Grout fills the void around the anchor, bonding the bar to the surrounding soil or rock.

- Load Transfer: It ensures that the loads from the anchor are properly transferred into the ground.

- Corrosion Protection: Grout acts as a protective layer around the steel bar, reducing exposure to moisture and chemicals.

- Improved Bearing Capacity: The right grout mix can significantly increase the system’s pull-out resistance.

Without proper grouting, even the best self drilling anchor system may underperform or fail prematurely.

Types of Grout Used

Selecting the right grout is vital for the overall success of the anchor installation. Common types include:

- Cementitious Grout: The most commonly used grout in self drilling anchor systems, made from Portland cement, water, and sometimes additives to enhance flow and strength.

- Resin Grout: Used in environments where rapid setting is needed or in chemically aggressive soils.

- Microfine Cement Grout: Suitable for fine soils or where deep penetration is required.

The experts at Argentium recommend conducting a soil analysis before choosing the grout type, ensuring optimal bond strength and long-term durability.

Grouting Techniques in Self Drilling Anchor Systems

There are three major techniques for grouting in a self drilling anchor system, each selected based on ground conditions and project requirements:

1. Simultaneous Drilling and Grouting

This is the most common technique. Grout is injected during the drilling process, which ensures complete filling of the borehole and minimizes the risk of ground collapse.

2. Post-Grouting

Here, grout is injected after the anchor is fully installed. This method allows for high-pressure grouting to fill any voids and create stronger bonds, especially in coarse or fractured ground.

3. Pre-Grouting

Used in very loose or sandy soils, where pre-grouting solidifies the surrounding ground before anchor installation, making the drilling process more controlled.

Proper grouting technique, combined with high-quality materials from trusted providers like Argentium, guarantees a reliable and efficient anchoring solution.

Grouting Best Practices

To ensure maximum effectiveness of the self drilling anchor system, follow these best practices:

- Use the Right Equipment: High-pressure grout pumps and mixers ensure consistent flow and avoid segregation of materials.

- Monitor Flow Rate and Pressure: Consistent flow and pressure during grouting prevent gaps and air pockets in the borehole.

- Flush the System: Before starting, make sure the hollow anchor bar and pump system are clean to avoid blockages.

- Control Grout Mix: Maintain a water-cement ratio that balances flowability with strength. A typical ratio is 0.4 to 0.5.

- Cure Time: Allow adequate curing time for grout to gain strength before applying load to the anchor.

When using premium-grade systems like those offered by Argentium, following these practices can significantly improve both safety and structural integrity.

Common Challenges and How to Overcome Them

- Blockages in the Bar: Use clean grout and flush the system before use to prevent clogging.

- Grout Leakage: In fractured ground, use additives or pre-grouting to prevent loss of grout.

- Inadequate Mixing: Invest in quality mixers to achieve a homogenous grout mix.

- Air Pockets: Continuous grout flow and proper venting prevent air entrapment, which can weaken the bond.

Even with advanced equipment, problems can arise. The key lies in operator training and strict adherence to protocols, areas where Argentium provides extensive technical support and training resources.

Environmental and Safety Considerations

Grouting in a self drilling anchor system must be performed responsibly:

- Environmental Compliance: Use low-impact additives and prevent grout spillage.

- Safety Gear: Workers should wear PPE, including gloves, masks, and goggles during the grouting process.

- Site Preparation: Secure the site to prevent unauthorized access during grouting.

Ensuring environmental and worker safety is part of the commitment to quality and professionalism that brands like Argentium bring to every project.

Conclusion

Grouting is the backbone of the self drilling anchor system, providing strength, durability, and stability to any anchoring project. Whether you’re stabilizing slopes, reinforcing foundations, or constructing tunnels, understanding and implementing proper grouting techniques is essential.

From selecting the ideal grout mix to applying the correct installation techniques, every stage in the anchoring process contributes significantly to long-term strength and stability. Adhering to best practices, proper safety standards, and precise application methods ensures that your self-drilling anchor system performs efficiently under varying site conditions. The right approach not only enhances durability but also minimizes maintenance needs and structural risks.

Partnering with trusted names like Argentium adds another layer of assurance. Their premium-quality anchoring systems are the result of advanced engineering, rigorous testing, and decades of expertise. With Argentium, you don’t just receive high-performance materials—you gain access to comprehensive technical support and expert guidance designed to help you achieve flawless installations every time.

In the end, success lies in the combination of superior products and meticulous workmanship. When you invest in the right materials and follow precise installation protocols, your self-drilling anchor system becomes more than just a support—it becomes a symbol of enduring reliability. Anchored strong, grouted with precision, and built for longevity, your project will stand firm against time and environmental challenges, reflecting the true essence of engineered excellence.

Leave a Reply