Metal hose assemblies are essential components in modern industries that demand flexibility, durability, and leak-free performance. Whether used in chemical plants, refineries, or food processing facilities, these assemblies ensure safe transfer of fluids and gases under extreme conditions. They offer exceptional resistance to pressure, temperature, and corrosion—making them the preferred choice over conventional rubber or plastic hoses.

In this guide, we’ll explore what metal hose assemblies are, their structure, types, applications, benefits, and how to choose the right one for your operation.

What Are Metal Hose Assemblies?

Metal hose assemblies consist of a flexible metal hose paired with end fittings to create a ready-to-use, leak-proof system. The hose is usually made of stainless steel, ensuring flexibility and resistance to high temperatures and corrosive materials. The fittings can be customized based on the system’s pressure and connection requirements.

These assemblies are designed to handle applications that involve vibration, thermal expansion, and movement where rigid piping would fail. Unlike standard hoses, they maintain performance under severe mechanical stress while maintaining full flow efficiency.

If you want to explore a wide range of reliable metal hose assemblies, you can check manufacturers that specialize in high-performance hose systems for industrial use.

Structure and Components of Metal Hose Assemblies

A metal hose assembly is more than just a flexible tube. It’s a carefully engineered product made of several integrated components:

1. Corrugated Metal Hose

The core of every assembly is the corrugated hose. Corrugations enhance flexibility and pressure resistance. Stainless steel is the most common material due to its corrosion resistance and temperature tolerance.

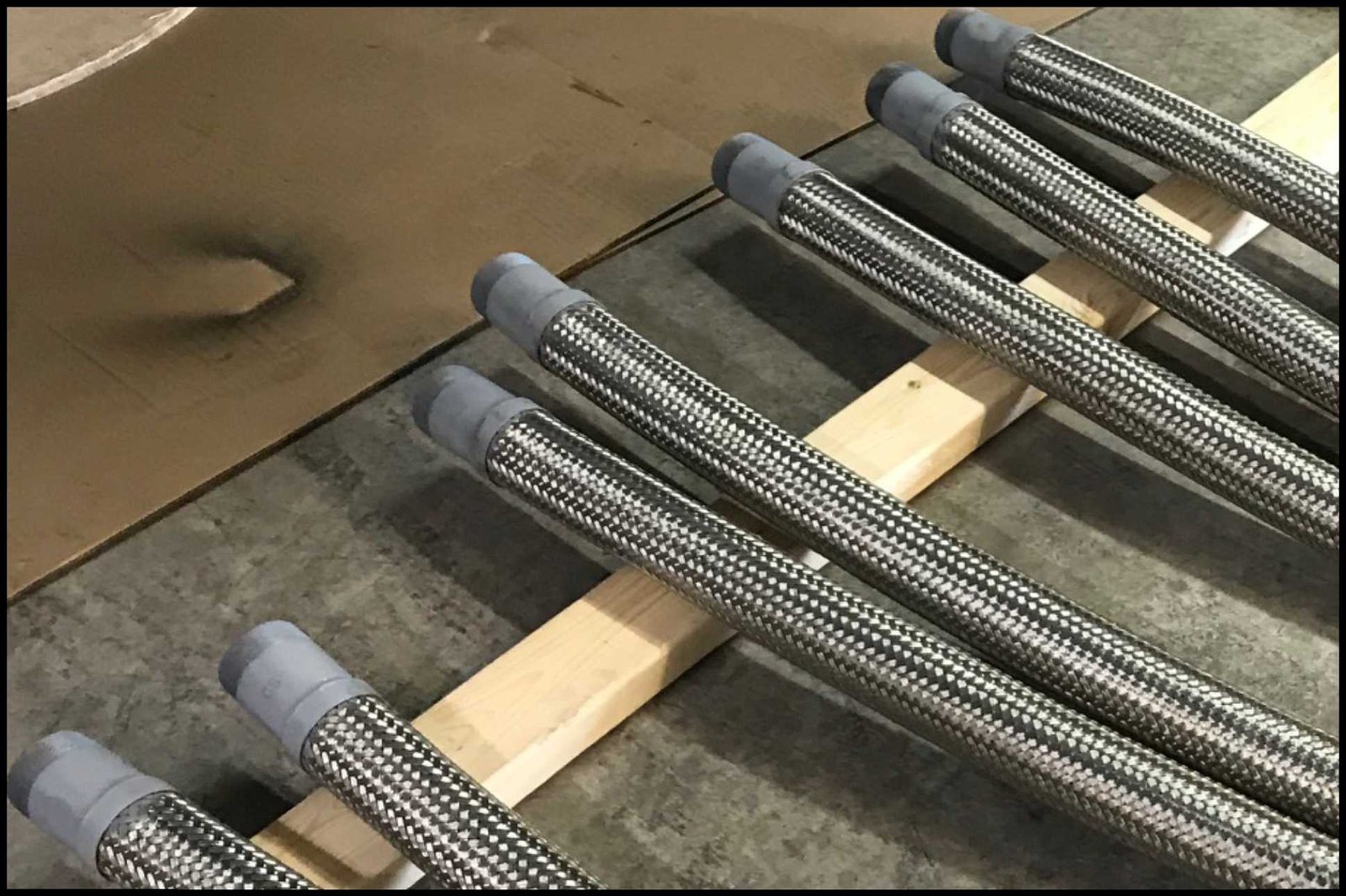

2. Braid or Wire Reinforcement

A braided layer surrounds the hose to prevent elongation and increase pressure capability. The braid also helps absorb vibration and external mechanical impact.

3. End Fittings

End fittings connect the hose to the system. Common fitting types include flanged, threaded, welded, and quick-connect styles. The fitting choice depends on the operating pressure, temperature, and installation requirements.

4. Protective Covers

For harsh environments, assemblies may include external covers or sleeves to prevent abrasion, protect against sparks, or resist chemical exposure.

Types of Metal Hose Assemblies

Different industrial needs require specific hose types. Below are the most widely used designs:

1. Annular Corrugated Hoses

These hoses feature individual circular corrugations perpendicular to the hose length. They offer high flexibility and are suitable for most general-purpose industrial uses.

2. Helical Corrugated Hoses

Helical hoses have a continuous spiral corrugation, offering better crush resistance and smooth flow paths. They are used in vacuum applications or where tight bending is required.

3. Braided Metal Hoses

A single or double braid can be added to enhance pressure ratings. Double-braided hoses are ideal for high-pressure systems or environments with strong vibration.

4. Stripwound Hoses

These are interlocked or overlapped metal strips that provide flexibility with high mechanical strength. They are often used for exhaust, suction, or dry material transfer.

Key Benefits of Metal Hose Assemblies

Metal hose assemblies offer several significant advantages across industries:

1. High Temperature and Pressure Resistance

These assemblies can withstand extreme temperatures from cryogenic levels up to several hundred degrees Celsius. Their robust construction ensures performance in both low and high-pressure environments.

2. Corrosion and Chemical Resistance

Stainless steel and other alloy materials resist corrosion and chemical attack. This makes them ideal for applications involving acids, oils, and gases.

3. Vibration and Noise Absorption

By flexing and absorbing vibration, these hoses reduce mechanical stress on equipment. They also minimize noise transmission in dynamic systems.

4. Durability and Longevity

Metal hoses outlast rubber and plastic alternatives. Their resistance to wear and deformation ensures long service life, reducing maintenance costs.

5. Leak-Proof Performance

With proper welding and fitting, metal hose assemblies provide tight seals that prevent leaks, ensuring safety and environmental protection.

Common Industrial Applications

Metal hose assemblies serve a wide range of industries due to their versatility and performance.

1. Oil and Gas Industry

They are used to transport hot oil, steam, or corrosive chemicals safely under extreme conditions.

2. Chemical and Petrochemical Plants

These assemblies handle aggressive fluids, acids, and gases that would degrade non-metal hoses.

3. Power Generation

In power plants, they help absorb movement caused by temperature changes and equipment vibration.

4. HVAC and Refrigeration

Flexible metal hoses are installed to connect compressors, pumps, and heat exchangers, reducing vibration transmission.

5. Food and Pharmaceutical Processing

Hygienic-grade stainless steel hoses ensure sanitary transport of ingredients and maintain cleanliness standards.

How to Choose the Right Metal Hose Assembly

Selecting the correct hose assembly is crucial for system reliability and safety. Consider the following factors:

1. Pressure Rating

The hose must handle both static and dynamic pressures in your system. Always choose a hose with a pressure rating higher than the operating pressure.

2. Temperature Range

Check the temperature limits of both the hose and fittings. Excessive heat can weaken the braid or cause expansion beyond safe limits.

3. Media Compatibility

Ensure the hose material is compatible with the fluid or gas being transferred. Chemical resistance charts can help in this selection.

4. Movement and Flexibility

Determine the type of movement (axial, lateral, or angular) expected in your application. The correct design prevents fatigue and premature failure.

5. Fitting Type and Size

Choose fittings that match the connection type of your equipment to ensure leak-proof installation.

6. Environment and Safety

If the hose operates in an abrasive or corrosive environment, consider protective covers or specialized materials like Inconel or Monel.

Maintenance and Inspection Guidelines

Proper maintenance extends the service life of metal hose assemblies. Follow these essential practices:

- Visual Inspection: Regularly check for kinks, wear, or corrosion.

- Leak Testing: Conduct periodic pressure tests to ensure seal integrity.

- Avoid Over-Bending: Maintain the manufacturer’s recommended minimum bend radius.

- Replace Damaged Assemblies: Do not attempt to repair a cracked or frayed hose; replacement is safer and more reliable.

The Future of Metal Hose Assemblies

Advancements in manufacturing and metallurgy continue to enhance hose performance. New alloys and precision welding techniques are enabling lighter, stronger, and more flexible assemblies. Automation and robotics now play a major role in ensuring consistent quality across large-scale production.

Additionally, industries are shifting toward predictive maintenance using sensors embedded in hoses to detect leaks or fatigue before failure occurs. This proactive approach boosts safety and reduces downtime.

Final Thoughts

Metal hose assemblies are indispensable in industries where flexibility, pressure resistance, and safety are top priorities. Their ability to perform in extreme conditions makes them a reliable solution for fluid and gas transfer. By choosing the right design, maintaining it properly, and following best installation practices, you can ensure optimal system performance and longevity.

Leave a Reply