A meat slicer machine does more than just cut. It shapes how shops, delis, and supermarkets serve their customers. Whether used to slice beef, chicken, or cold cuts, these machines must run smoothly to keep the workday flowing. Even a slight fault can cause long delays or unsafe handling. That’s why regular maintenance matters—and why finding the right service partner in Malaysia makes a real difference.

Why Regular Service Helps Every Meat Slicer Machine?

Routine service protects your investment. Meat slicers face constant wear from hard surfaces, heat, and movement. Over time, these forces reduce cutting power and slow down production. Without service, this small drop grows into bigger problems—safety risks, food waste, or costly downtime.

How to Spot a Quality Service Provider?

You don’t need a full team of engineers to maintain one machine. But you do need a partner who knows how to handle one. Many companies in Malaysia promise support—but only a few actually deliver. So, how can you tell who’s reliable?

Look for these signs:

1. Deep Experience with Food Retail Equipment

Not all technicians understand meat slicers. A quality provider will already handle equipment in supermarkets, hypermarkets, and speciality food stores. They’ll know what brands exist in Malaysia and how each works inside and out.

Fast Response for Repairs

Machines often stop working during peak hours. A good partner won’t delay or offer excuses. They’ll answer calls, show up on time, and get to work quickly.

Clear Process and Reporting

You need more than a “fix.” You need clear records. Look for companies that log every visit, explain what they check, and share steps taken. This makes your job easier when it comes time for audits or inspections.

What Should a Maintenance Visit Include?

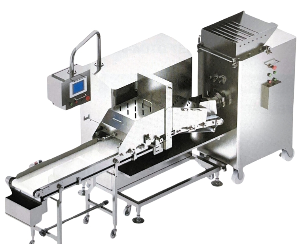

Service checks must go beyond a quick wipe. A skilled technician will open the unit, remove parts, and inspect the core functions of the meat slicer machine/meat chopper machine. Below is a helpful table that explains what a proper service includes:

What Gets Checked During a Standard Service?

| Service Task | Why It Matters |

| Blade sharpening or replacement | Keeps slices clean and uniform |

| Motor function test | Ensures smooth rotation and speed |

| Gear and belt inspection | Avoids sudden breakdowns |

| Deep cleaning of internal parts | Stops food build-up and bacteria growth |

| Safety guard and sensor checks | Protects users from injuries |

| Power cord and switch review | Prevents short circuits and power loss |

Why Meat Slicer Machines Demand Special Care?

Unlike other kitchen tools, slicers must work with power and precision. One small flaw—like a loose screw or sticky motor—can cause uneven cuts or force a full stop. These machines deal with raw meat, so hygiene also plays a big role. Missed cleaning steps can allow bacteria to grow.

That’s why meat slicer machines need trained service. General electricians or regular maintenance teams might miss key problems. But a specialist will recognise early signs of wear and repair them before they grow.

Hubs Technology: Trusted in Supermarket and Equipment Maintenance

Among companies known for professional store support, Hubs Technology stands tall. They work across many sectors—from supermarkets to home stores—and deliver sharp, reliable service for in-store machinery.

Though they focus on retail engineering and installation, their deep roots in Malaysia’s grocery and food industries place them close to key tools like meat slicer machine. Their work includes regular site servicing, custom setup, and equipment inspection—all key parts of slicer upkeep.

Keep Slicer Machines Working Longer with the Right Partner

You don’t need to replace your meat slicer machine every few years. You only need to maintain it well. With the right care, even a busy machine can stay sharp and steady for much longer than expected.

Your service provider should help you:

- Avoid downtime

- Replace worn-out parts before they break

- Sharpen blades before they dull

- Keep hygiene levels high

- Teach your staff simple care steps

These services protect both your machine and your team.

Signs Your Machine Needs Service Soon

Don’t wait until a full stop. Look out for early signs. If you notice even one of the problems below, call a service team.

- Slices look jagged or uneven

- Blade pulls or sticks during cuts

- Loud grinding or buzzing sounds

- The machine vibrates or moves during use

- Power turns on and off

- Food gets stuck too often

Choosing the Right Company Saves More Than Money

When you find the right team to handle your slicer, you don’t just save money. You also save time, energy, and stress. You stop chasing support or fixing mistakes yourself. Instead, your machines hum through each day, and your staff stays focused on serving your customers.

Hubs Technology brings this kind of support. They manage complex store setups and keep many kinds of retail machines running smoothly. Their field experience covers every level of service—from one store to a full supermarket chain.

When your slicer needs help, they stand ready to handle it.

Steps to Keep Your Meat Slicer Running Smoothly

You can’t stop every fault. But you can stop most of them. Follow these steps to stretch your machine’s life and performance:

Step 1: Clean After Every Use

Wipe down surfaces, clear food bits, and check that no grease builds up. Clean machines last longer.

Step 2: Sharpen the Blade Often

Don’t wait for dull slices. Sharpen your blade once a week—or more, if you use it daily.

Step 3: Avoid Overloading

Don’t force thick cuts or hard items into the slicer. Cut by weight and angle, not by strength.

Step 4: Call for Regular Service

Set a schedule. Don’t wait for a fault. Let the pros check your machine once every three months.

How Often Should You Book Maintenance?

Service frequency depends on how often you use the meat slicer machine. A shop that slices meat all day needs more service than a café that uses it twice a week.

Here’s a general guide:

- Daily Use (Retail or Butcher): Service every 3 months

- Weekly Use (Restaurant): Service every 6 months

- Light Use (Small Cafe): Service once a year

Final Thoughts

A well-maintained meat slicer machine keeps your business running clean and smoothly. You don’t just cut better—you serve better. You save time. You build trust with your customers.

In Malaysia, many companies offer general services, but only a few understand these machines fully. That’s why working with a seasoned provider like Hubs Technology gives you peace of mind. Their long experience with food retail systems places them in the right spot to support your meat slicers, too.

FAQ’s

- Why do meat slicer machines require regular maintenance?

Regular maintenance keeps blades sharp, motors efficient, and safety features reliable. It prevents breakdowns, extends machine lifespan, and ensures consistent slicing quality in foodservice and retail businesses.

- What services are usually included in meat slicer maintenance?

Typical services include blade sharpening, motor inspection, lubrication, electrical testing, alignment checks, and safety feature calibration. Technicians also clean and sanitise machines to maintain hygiene standards.

- What signs show a meat slicer needs servicing?

Warning signs include uneven slicing, excessive noise, overheating, blade dullness, or difficulty starting. Ignoring these issues may lead to costly breakdowns or unsafe operation.

Leave a Reply