In today’s industrial world, efficient bulk-material handling is essential to keep production running smoothly, safely, and cost-effectively. One piece of equipment that plays a pivotal role in many industries is the screw conveyor. Whether you’re transporting powders, granules or coarse materials, the right screw conveyor can make all the difference. If you are searching for a reliable screw conveyor manufacturer or screw conveyor supplier, then you’ll want to understand what features matter, how to pick the right one, and why a trusted vendor counts. In this blog, we’ll unpack the key aspects of screw conveyors, highlight the benefits of working with a top-tier screw conveyor supplier/manufacturer, and review what to look for in a machine like the one offered by Buraq Engineering.

What is a Screw Conveyor?

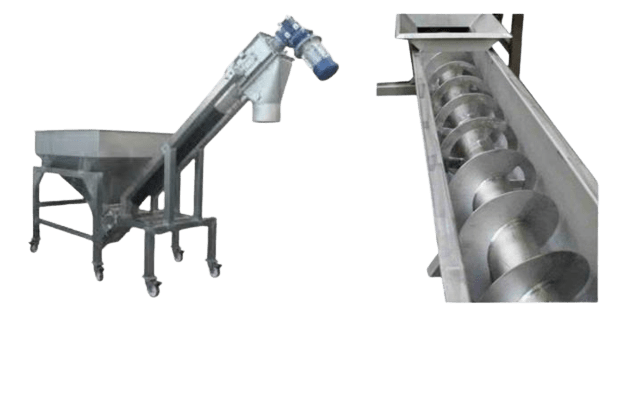

A screw conveyor is a mechanical conveying device that uses a rotating helical screw (also called an auger) inside a tube or trough to move material from one point to another. Because of its simplicity and versatility, the screw conveyor finds broad application across industries such as food processing, chemical, pharmaceutical, agriculture, and manufacturing.

The advantages of this design include relatively low cost, compact footprint, enclosed configuration (good for dust or hygiene control), and flexibility in terms of material type and layout. That said, not all screw conveyors are created equal — choosing the right screw conveyor manufacturer and screw conveyor supplier ensures you get the features, build quality and service you need.

Why Choose a Specialized Screw Conveyor Manufacturer?

When you work with a purpose-built screw conveyor manufacturer, rather than a generic conveyor company, you benefit in several critical ways:

1. Tailored design & construction

A dedicated manufacturer understands the nuances of screw conveyors: flight designs, pitch spacing, tube vs trough, material compatibility, and service conditions (wear, corrosion, hygiene). The Buraq Engineering product page emphasises that their screw conveyor systems are “customisable … in various lengths, capacities, and screw types to meet specific material handling needs.”

2. Robust build & reliability

The manufacturer will select appropriate materials (e.g., stainless steel for food or hygiene applications, carbon steel for general purpose), bearings, motors and drive assemblies sized for the duty. For example, the page states: “Robust Construction: Built for longevity and consistent performance in challenging environments.”

3. Ease of operation and maintenance

A quality manufacturer will design for safe, convenient operation, and make maintenance accessible. The page calls out “User-Friendly Design: Easy to operate with low maintenance requirements.”

4. Support & service from a trusted supplier

When a manufacturer also acts as your screw conveyor supplier, you gain a partner who can help specify, install, troubleshoot and service the equipment.

Key Features to Look For When Choosing a Screw Conveyor

Whether you are sourcing a conveyor from Buraq or another vendor, as a buyer you should keep your eye on these features:

Customisable capacity and layout

Make sure the conveyor can be matched to your process flow: length, incline angle, screw diameter and pitch, trough or tube style, loading/unloading points. The value of a flexible manufacturer is that they can adapt these parameters to your needs.

Material compatibility

Depending on what you convey (powders, granules, sticky materials, corrosive chemicals), you’ll need appropriate materials of construction, flight design (e.g., ribbon vs solid), sealing to prevent dust, and maybe cleaning access for hygiene. The Buraq-page says the conveyor is “safe, convenient, and hygienic to use.”

Drive and mechanical robustness

Look for proper motor sizing, gearbox, bearings, mounting rigidity, protection from overload and dust. A good screw conveyor manufacturer will size drives appropriately and design for industrial duty.

Ease of cleaning & service

If your application is food, pharma or hygiene-sensitive, cleaning access, smooth surfaces, and minimal dead zones matter. The “user-friendly design” note on the Buraq conveyor suggests maintenance ease is built in.

Hygiene and safety features

Safety features to protect operators and materials—guards, covers, safe access—are essential. The Buraq page mentions “advanced safety features to protect both operators and materials.”

Global & local support

If you’re operating in Europe, Africa or Asia, working with a screw conveyor supplier/manufacturer that has global reach or export experience helps with logistics, spares & service.

Why Work with Buraq Engineering as Your Screw Conveyor Supplier?

Based on the product page we reviewed, here are some of the standout reasons to consider Buraq Engineering as your screw conveyor manufacturer & supplier:

-

Their product is marketed specifically under the heading “Screw Conveyor Manufacturer and Supplier”, making clear their dual role.

-

They emphasise customisation: different lengths, capacities, screw types to match customer needs. This flexibility reduces the risk of mismatch.

-

They highlight robustness and industrial suitability: “built for longevity and consistent performance in challenging environments”.

-

They highlight hygiene and convenience: “safe, convenient, and hygienic to use”. This is critical in industries like food and pharmaceuticals.

-

They convey a global mindset: “We offer reliable and efficient solutions for bulk material handling worldwide.”

-

They explicitly invite contact for a quote, showing a willingness to engage and provide tailored solutions.

Use-Cases & Applications of Screw Conveyors

Screw conveyors are used in many sectors thanks to their adaptability. Some examples:

-

Food processing: moving powders, granules, flakes or ingredients from one stage to another in a clean, enclosed manner.

-

Chemical and pharmaceutical: handling fine powders, granules, or raw materials with controlled dust and contamination.

-

Agriculture: conveying grain, feed, seeds, or fertilizer in horizontal or inclined configurations.

-

Manufacturing and processing plants: moving raw materials, by-products, waste or finished goods in bulk.

-

Waste & recycling: handling materials like wood chips, biomass, sludge or other coarse materials.

Because the screw conveyor can be configured for length, capacity and layout, a reputable screw conveyor manufacturer will adapt the design to the specific material and environment. For example, if you have sticky or abrasive material, the screw flights and trough material might need special treatment.

Choosing the Right Supplier

To ensure you’re working with a trustworthy screw conveyor supplier/manufacturer, here are some questions you should ask:

-

Can you customise the conveyor length, screw diameter/pitch and material of construction to suit my material and layout?

A supplier that offers standard only might force compromises. -

What materials and finishes are used in construction?

Especially for food, pharma, or corrosive environments: stainless steel, hygienic finishes, welded seams, minimal dead zones. -

What kind of drive/gearbox/bearing configuration is used and how is it sized?

Ensure it’s rated for your duty, has overload protection and spare parts availability. -

What cleaning, maintenance and access features does the design include?

Safe access, covers, inspection ports, easy removal of screw flights if needed. -

What safety features are built in?

Covers or guards, emergency stops, minimal exposed moving parts, safe flow design. -

What service and support do you provide?

Warranty terms, spare parts availability, local support if you’re in Europe or elsewhere. -

Do you have experience with similar applications?

Ask for references or case studies—does the manufacturer have real-world installations across sectors?

Final Thoughts

In summary, if you are searching for a robust, efficient and customized bulk material handling solution, investing in a high-quality screw conveyor machine from a reliable screw conveyor manufacturer and supplier is a wise decision. The right machine will deliver smooth flow of materials, reduce downtime, ensure operator safety, and support your production goals.

Leave a Reply