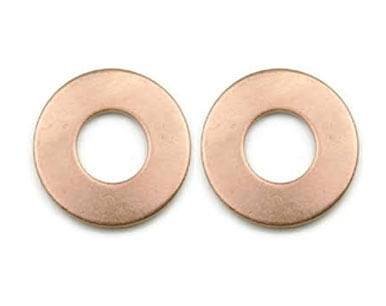

In the vast world of mechanical components, fasteners, and fittings, the humble washer is often overlooked. It is a simple, disk-shaped component, but its role is absolutely critical. A washer’s primary job is to distribute the load of a threaded fastener, but depending on its design and material, it can also be called upon to lock, space, or, most importantly, create a powerful seal.

While steel and stainless steel are commonplace, there are many applications where these materials are simply not the best choice. For high-performance applications in the automotive, electrical, and plumbing industries, engineers turn to a different material: copper.

A copper washer is not just a load distributor; it is a high-performance sealing and conductive component. Its unique set of properties makes it an indispensable problem-solver for challenges ranging from high-pressure fluid leaks to efficient electrical grounding. This article explores the properties, applications, and key benefits of using copper washers.

What Makes Copper a Unique Material for Washers?

Copper is one of the oldest metals used by civilization, and its value persists for good reason. Its unique atomic structure gives it a set of physical properties that are almost perfectly suited for specialized engineering tasks.

Unlike hard, rigid steel, copper’s primary advantage is its softness and malleability. In the world of fasteners, where hardness is often prized, this ductility is actually a superpower. It allows the copper to deform and flow into microscopic imperfections when clamped, creating a seal that harder materials cannot achieve.

Furthermore, copper is the benchmark standard for electrical and thermal conductivity. It is also highly resistant to corrosion in many environments and is non-sparking, making it a safe choice for volatile applications. These core characteristics—softness, conductivity, and durability—define the copper washer’s role.

The Key Properties of Copper Washers in Detail

To understand where and why copper washers are used, one must first look at their specific properties. Each feature makes them the ideal choice for a particular set of problems.

1. The Unmatched Sealing Capability

This is the most common reason for choosing a copper washer. Copper is an extremely ductile metal, meaning it is soft and can be easily deformed without breaking. When a copper washer is placed between two surfaces (like the head of a bolt and a flat surface) and torque is applied, the washer “crushes” slightly.

This crushing action is the entire point. The soft metal flows and fills any microscopic gaps, scratches, or imperfections in the mating surfaces. This creates an incredibly tight, form-fitting gasket.

- Result: A metal-to-metal seal that is exceptionally resistant to leaks. It can contain fluids (like oil, water, or fuel) and gases (like air or refrigerants) even under high pressure and at high temperatures.

- Annealed Copper: For maximum sealing, copper washers are often “annealed.” This is a heat treatment process where the copper is heated and slowly cooled, which relieves internal stresses and makes the metal as soft as possible, maximizing its sealing ability.

2. Superior Electrical & Thermal Conductivity

Copper’s properties as a conductor are legendary. It has the highest electrical conductivity of any non-precious metal.

- Electrical Conductivity: When used in an electrical connection, such as a grounding strap or a busbar, a washer’s job is to ensure a reliable path for the current. A steel washer would introduce high resistance, impeding the flow and generating heat. A copper washer does the opposite; it provides a large, clean surface area for maximum current transfer with minimal resistance.

- Thermal Conductivity: This same property allows copper to be an excellent conductor of heat. In electronics or machinery, copper washers can be used as “thermal shims” or as part of a heat sink assembly, helping to draw damaging heat away from a critical component and dissipate it into the air or a larger heat sink.

3. High Corrosion Resistance

Copper has a good-to-excellent resistance to corrosion from a wide range of elements. While it does not “rust” like iron, it does oxidize. This oxidation forms a distinct blue-green “patina” (copper oxide-sulfate). This patina layer is non-flaking and actually forms a protective, non-porous skin over the copper, shielding the metal underneath from further attack. This makes it a durable choice for plumbing, marine, and outdoor applications.

4. Non-Sparking Properties

In environments where flammable gases, fuels, or solvents are present, a single spark from a tool or a component can be catastrophic. Steel fasteners can create a friction spark if struck. Copper, being a softer, non-ferrous metal, is “non-sparking.” This makes copper washers an essential safety component in fuel systems, chemical plants, and explosive environments.

5. Anti-Galling Characteristics

“Galling,” or cold-welding, is a common and destructive problem when using stainless steel fasteners. Under high pressure, the threads of a stainless bolt and nut can seize together so tightly that they cannot be separated, often requiring the bolt to be cut off. Copper, being a softer, dissimilar metal, acts as an anti-galling agent. Using a copper washer (or copper-based anti-seize) disrupts the metal-on-metal contact and prevents the threads from welding themselves together.

Key Industrial & Commercial Applications

The properties of copper washers directly translate into their wide-ranging applications. They are found in virtually any industry that values leak-free performance, electrical efficiency, or safety.

1. Automotive, Marine, and Small Engines

This is one of the largest users of copper washers, specifically for sealing.

- Oil Drain Plugs: Nearly every car uses a crushable copper (or aluminum) washer on the oil drain plug. It deforms to create a perfect seal against the oil pan, preventing leaks.

- Brake and Clutch Lines: Hydraulic brake and clutch systems use “banjo bolts” to connect fluid lines to components like calipers and master cylinders. These connections are almost exclusively sealed with copper crush washers to contain the high-pressure brake fluid.

- Fuel Injector Seals: Copper washers are used to seal the base of fuel injectors, preventing combustion gases from leaking out and fuel from leaking in.

- Marine Applications: In boating, copper washers are used in electrical grounding systems and in through-hull fittings where corrosion resistance to saltwater is vital.

2. Electrical and Electronics

In the electrical world, washers are a non-negotiable component for high-current applications.

- Grounding Connections: They are used to secure grounding straps to a vehicle chassis or an electrical panel, ensuring a reliable, low-resistance path to earth.

- Busbar Assemblies: In power distribution panels, thick copper bars called busbars are used to carry massive currents. Copper washers are used with the bolts that join these bars, maximizing the surface-to-surface contact and ensuring the most efficient power transfer possible.

- Electronics: They are used in heat sink assemblies for CPUs and power transistors, helping to conduct heat away effectively.

3. Plumbing, HVAC, & Hydraulics

Anywhere fluids or gases are moved, sealing is a top priority.

- Hydraulic Fittings: In high-pressure hydraulic systems (like on construction equipment), copper washers are used to seal connections on pumps, valves, and hoses, preventing leaks that are both dangerous and messy.

- Pneumatic Systems: They are used to seal air line fittings in compressed air systems.

- HVAC: Copper washers are found in pressure gauges, valves, and fittings within air conditioning and refrigeration systems, effectively sealing refrigerants.

- General Plumbing: They are often used in valves and high-end fixtures to provide a robust, long-lasting seal that is superior to a standard rubber washer, especially in high-temperature water

Leave a Reply