In the competitive world of detergent manufacturing, achieving consistent product quality, uniform blending of ingredients, and efficient production are critical success factors. Whether producing powdered detergents for household use or specialized formulations for industrial cleaning, mixing lies at the heart of the process.

One of the most effective and widely adopted technologies for this purpose is the ribbon blender mixer. Designed for homogenous blending of dry powders, granules, and even light pastes, this equipment ensures optimal consistency and product performance while minimizing energy consumption and production time.

In this comprehensive guide, we’ll explore how ribbon mixers enhance detergent production, their working principles, benefits, and tips for optimizing their performance on the production floor.

Understanding the Role of Mixing in Detergent Production

The detergent manufacturing process involves combining multiple ingredients such as surfactants, builders, fillers, fragrances, colorants, and active agents. Achieving a perfectly uniform blend is essential for product stability and effectiveness.

Even minor inconsistencies can lead to variations in cleaning performance, foam generation, or fragrance intensity. Hence, manufacturers rely on efficient mixers to ensure all ingredients are evenly distributed — maintaining batch-to-batch consistency and maximizing product quality.

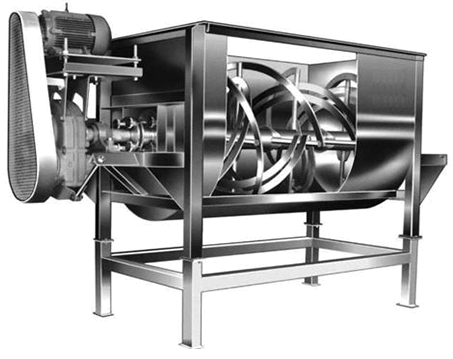

This is where the ribbon blender mixer comes into play. Its design, which incorporates helical ribbons moving in opposite directions, enables thorough and rapid mixing, ensuring that each detergent particle receives an equal distribution of active ingredients.

What Is a Ribbon Mixer?

A ribbon mixer is a horizontal, U-shaped mixing machine equipped with a specially designed agitator that features inner and outer helical ribbons. These ribbons rotate simultaneously in opposite directions, moving materials both radially and laterally within the mixing chamber.

This dual-motion blending ensures that ingredients from every corner of the chamber are continuously folded and combined until a homogeneous mixture is achieved.

Ribbon mixers are ideal for dry powder formulations like detergent base powder, as they can handle bulk materials with minimal degradation and energy use. Depending on the production scale, these mixers are available in various sizes, from laboratory-scale units to large-capacity industrial systems.

Working Principle of a Ribbon Mixer in Detergent Production

The efficiency of a ribbon mixer lies in its simple yet highly effective mechanical motion. Here’s how it works step by step:

-

Loading the Ingredients

All detergent components — surfactants, fillers, colorants, and fragrances — are loaded into the mixer’s U-shaped trough. -

Mixing Action

Once the mixer is activated, the inner ribbon moves the materials in one direction while the outer ribbon pushes them in the opposite direction. This countercurrent motion results in continuous circulation and intermixing of all ingredients. -

Homogenization

The combination of radial and axial flow ensures a uniform distribution of all powders, preventing segregation or clumping. -

Discharge

After reaching the desired mixing uniformity, the batch is discharged through a bottom valve or door. The smooth interior design prevents residue buildup, ensuring a clean and efficient process.

This method provides rapid, uniform mixing — a must-have for consistent detergent quality.

Why Ribbon Mixers Are Ideal for Detergent Manufacturing

Detergent manufacturing involves complex formulations that demand uniform blending, precise ingredient distribution, and minimal heat generation. Ribbon mixers meet all these requirements effectively. Here’s why they stand out:

1. Superior Mixing Uniformity

The unique dual-ribbon design allows for both axial and radial movement of materials, ensuring that every ingredient is evenly distributed throughout the batch. This uniformity ensures the detergent’s cleaning efficiency and consistency remain the same across every package produced.

2. Gentle Yet Effective Mixing

Detergent powders are often delicate and can lose their functional properties under excessive mechanical stress. Ribbon mixers provide a gentle mixing motion, preserving particle integrity while achieving a thorough blend.

3. Versatility in Formulation

Ribbon mixers can handle a variety of detergent formulations — from dense washing powders to lightweight granules. They are also compatible with additives like perfumes, enzymes, and colorants, which can be sprayed or added during mixing for even distribution.

4. High Productivity

With short mixing cycles and easy loading/unloading mechanisms, industrial ribbon mixers significantly improve throughput. The continuous or batch mixing options give manufacturers flexibility in scaling their production based on demand.

5. Energy Efficiency

Ribbon mixers require relatively low power compared to high-shear or planetary mixers, making them cost-effective for large-scale operations.

6. Easy Maintenance and Cleaning

The smooth interior surfaces and minimal moving parts make ribbon mixers easy to clean and maintain — a critical factor when switching between different detergent formulations.

Applications of Ribbon Mixers in Detergent Production

Ribbon mixers are used across multiple stages of detergent manufacturing. Their versatility allows manufacturers to process different formulations effectively, including:

-

Powder Detergents: Uniform blending of surfactants, fillers, and fragrances.

-

Laundry Powders: Ensuring even distribution of bleaching agents and enzymes.

-

Dishwashing Powders: Mixing cleaning agents with anti-caking additives.

-

Industrial Cleaning Agents: Creating strong, consistent formulations for commercial applications.

Additionally, some advanced ribbon mixers can handle semi-moist detergent pastes, enhancing versatility in production lines that handle both powder and cream-based detergents.

How to Optimize Ribbon Mixer Performance in Detergent Plants

To get the most out of your industrial ribbon mixer, manufacturers should focus on these optimization tips:

1. Accurate Loading

Ensure the mixer is loaded to the optimal capacity — typically between 40% to 70% of its total volume. Underfilling or overfilling can affect mixing efficiency and consistency.

2. Proper Mixing Time

Determine the ideal mixing time through testing. Overmixing can cause ingredient degradation, while undermixing leads to inconsistent batches.

3. Speed Control

Adjusting the agitator speed according to material type ensures gentle yet thorough mixing. Many modern ribbon mixers feature variable frequency drives (VFDs) for this purpose.

4. Uniform Ingredient Addition

Add liquids like fragrances or colorants slowly to prevent clumping. Spray systems or atomizers can be integrated for even dispersion.

5. Regular Maintenance

Periodic inspection of seals, bearings, and ribbons prevents downtime and ensures consistent operation. Keeping the mixer clean also prevents cross-contamination between different detergent batches.

Choosing the Right Ribbon Mixer for Detergent Manufacturing

Selecting the right ribbon mixer depends on several factors, including production capacity, product characteristics, and required mixing time. Here’s what to consider:

-

Capacity: Match the mixer size with your batch requirements.

-

Material Construction: Stainless steel is preferred for detergent manufacturing to prevent corrosion and contamination.

-

Power and Speed: Ensure the mixer offers variable speed control for flexibility.

-

Discharge System: Choose between manual or pneumatic discharge based on automation needs.

-

Customization Options: Some manufacturers offer optional features like spray nozzles, vacuum systems, and jacketed barrels for heating or cooling.

Working with a reputable equipment supplier ensures you get a durable, high-performance machine suited to your detergent formulation process.

Future Trends in Detergent Mixing Technology

With the increasing demand for eco-friendly and concentrated detergents, the future of mixing technology is shifting toward energy efficiency, automation, and precision control.

Modern ribbon mixers now feature smart sensors and automated control systems that monitor mixing time, temperature, and homogeneity in real-time. This digital transformation allows manufacturers to ensure consistent quality, minimize waste, and reduce energy consumption.

Furthermore, hybrid models that combine ribbon and paddle mixing mechanisms are emerging, offering faster mixing times and enhanced versatility for complex formulations.

Conclusion

Detergent production demands precision, consistency, and efficiency — qualities that the industrial ribbon mixer delivers effortlessly. With its unique helical design, gentle yet effective mixing action, and adaptability to diverse formulations, it remains one of the most reliable solutions in detergent manufacturing.

Leave a Reply