In today’s manufacturing world, plastic products are everywhere — from pipes and films to packaging and automotive components. But have you ever wondered how these uniform, continuous plastic shapes are made? The answer lies in plastic extrusion, a highly efficient manufacturing process that transforms raw plastic materials into endless shapes and sizes.

In this article, we’ll break down what plastic extrusion is, explore its step-by-step process, discuss key equipment, and understand why it remains one of the most widely used methods for shaping plastics across industries.

What Is Plastic Extrusion?

Plastic extrusion is a continuous manufacturing process in which raw plastic materials, usually in the form of pellets or granules, are melted and shaped into long, consistent forms such as pipes, sheets, profiles, or films.

Unlike molding (which creates discrete parts), extrusion produces continuous lengths of products that can be cut to size afterward. This makes it ideal for high-volume manufacturing where consistency, precision, and cost-efficiency are essential.

The process involves feeding plastic material into a heated barrel, where it’s melted, mixed, and forced through a specially designed die to form the desired shape. Once the product exits the die, it is cooled and solidified before being cut, wound, or coiled for packaging.

A Brief History of Plastic Extrusion

Plastic extrusion has been around since the 1930s, evolving from early rubber extrusion techniques. The introduction of thermoplastics like PVC, polyethylene, and polypropylene in the mid-20th century revolutionized the industry. Over time, advancements in extruder machine design, die precision, and automation have made the process faster, more efficient, and highly customizable.

Today, extrusion plays a vital role in nearly every industrial sector — construction, packaging, automotive, medical, and even aerospace.

Applications of Plastic Extrusion

Before diving into the step-by-step process, it helps to know where extruded plastics are commonly used. Some of the most popular applications include:

-

Pipes and Tubes: For water supply, irrigation, drainage, and medical use.

-

Sheets and Films: Used in packaging, insulation, and lamination.

-

Profiles and Channels: For windows, doors, trims, and weatherstripping.

-

Wire and Cable Coating: Extruded plastic insulation for electrical cables.

-

Filaments: Used in 3D printing and textile manufacturing.

From your car’s dashboard to the plastic wrapping on food, extrusion makes it possible to produce millions of identical parts efficiently.

Step-by-Step Plastic Extrusion Process

Let’s take a detailed look at how plastic extrusion actually works — from raw material feeding to finished product.

Step 1: Feeding the Raw Material

The process begins with feeding plastic pellets, granules, or powder into a hopper. These materials can be virgin resins, recycled plastics, or a mix of both.

Often, colorants, stabilizers, or additives are blended in at this stage to improve performance, color consistency, and durability of the final product. The hopper feeds the material gradually into the barrel of the plastic extruder machine, ensuring a continuous and uniform supply.

Step 2: Melting and Mixing

Inside the barrel, a rotating screw pushes the plastic material forward. As it moves, the material is subjected to controlled heat and pressure, gradually melting it into a homogeneous molten state.

The barrel is divided into multiple heating zones, each carefully set at increasing temperatures to prevent burning or uneven melting. The screw also ensures thorough mixing and homogenization so that the melted plastic has a consistent texture and color throughout.

Step 3: Filtering the Melt

Before shaping, the molten plastic passes through a screen pack and breaker plate. These components remove contaminants, unmelted particles, and impurities.

This step is essential for maintaining product quality and uniformity, ensuring that no defects or weak points form in the final extrusion.

Step 4: Shaping Through the Die

Once filtered, the molten plastic enters the extrusion die, which determines the shape and size of the final product. The die acts like a mold — but instead of enclosing the plastic, it allows it to flow continuously through a specific profile opening.

For instance:

-

A circular die produces pipes or tubing.

-

A flat die forms plastic sheets or films.

-

Custom-shaped dies create profiles like window frames or trims.

Precision die design is critical because even minor variations can affect product dimensions, surface finish, and performance.

Step 5: Cooling and Solidification

After exiting the die, the hot plastic profile needs to be cooled rapidly to retain its shape. The method of cooling depends on the product type:

-

Water Bath Cooling: Common for pipes, tubes, and profiles.

-

Air Cooling: Used for films, sheets, and delicate extrusions.

The cooling process must be carefully controlled to prevent warping, shrinkage, or deformation. Some systems use a combination of water spray and vacuum calibration to ensure accurate dimensions.

Step 6: Pulling and Sizing

Once cooled, the solidified product passes through a haul-off or puller system. This equipment maintains consistent tension and speed, ensuring uniform thickness and smooth surfaces.

In the case of pipes or profiles, sizing devices or calibration tools further refine the dimensions to meet precise specifications.

Step 7: Cutting or Winding

Finally, the continuous extrudate is either cut into specific lengths or wound onto reels.

-

Pipes and profiles are cut into desired sections.

-

Films and sheets are rolled for easy transportation.

After this stage, the products are ready for packaging, labeling, and quality inspection.

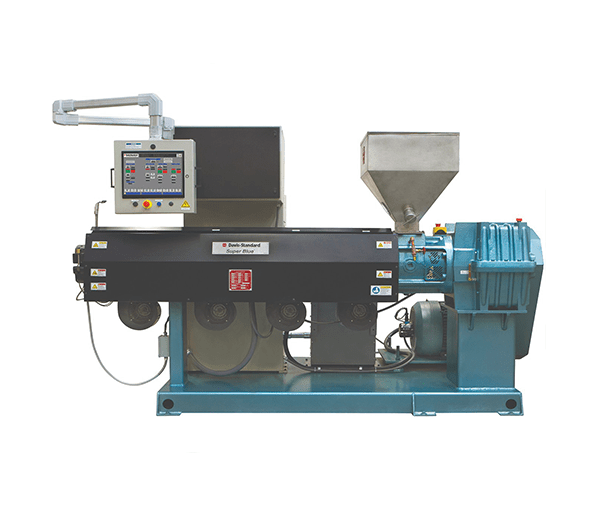

Key Components of a Plastic Extrusion Line

A complete extrusion setup involves several critical components working together seamlessly:

-

Hopper: Stores and feeds raw materials into the system.

-

Barrel and Screw: Responsible for melting, mixing, and conveying the plastic.

-

Heaters: Provide the required temperature along the barrel.

-

Screen Pack and Breaker Plate: Filter impurities from the molten plastic.

-

Die: Shapes the plastic into the desired form.

-

Cooling System: Solidifies and stabilizes the extrusion.

-

Haul-Off Unit: Maintains consistent extrusion speed.

-

Cutter or Winder: Finalizes the product for packaging.

Each component must operate in perfect sync for efficient, high-quality extrusion output.

Types of Plastic Extrusion

Depending on the product and material type, manufacturers may use different extrusion methods:

-

Sheet and Film Extrusion: For producing flat plastic sheets and films.

-

Pipe and Profile Extrusion: For tubes, rods, and custom shapes.

-

Blown Film Extrusion: For making thin plastic films used in packaging.

-

Co-Extrusion: Combines multiple layers of materials for enhanced properties.

-

Over-Jacketing Extrusion: Used to coat wires and cables with insulation.

Each type requires slight variations in die design, cooling technique, and process parameters.

Advantages of Plastic Extrusion

Plastic extrusion offers several benefits that make it one of the most preferred manufacturing methods worldwide:

-

High Production Efficiency: Continuous operation ensures fast output.

-

Low Material Waste: Regrind or scrap can be reused.

-

Consistent Quality: Uniform cross-sections and dimensional accuracy.

-

Versatility: Works with a wide range of thermoplastics.

-

Customization: Easy to produce different profiles and sizes.

-

Cost-Effective: Lower tooling and maintenance costs compared to molding.

The Future of Plastic Extrusion

Modern extrusion technology is rapidly evolving. Automation, AI-driven process monitoring, and sustainable materials are shaping the future of the industry.

Manufacturers are increasingly adopting energy-efficient plastic extruder machines that minimize waste and enhance throughput. Additionally, eco-friendly bioplastics and recycled materials are becoming mainstream, aligning extrusion processes with global sustainability goals.

Conclusion

Plastic extrusion is a cornerstone of modern manufacturing — a process that turns simple plastic pellets into countless everyday products. From pipes and packaging films to automotive parts and 3D printing filaments, extrusion makes large-scale, precise production possible.

Leave a Reply